Introduction

Obtaining abattoir-based evaluations, specifically skin lesions, on individual sows immediately before harvest could provide producers and processors with value and welfare-based information. These evaluations have utility in estimating how the location and severity of bruises and abscesses affect usable product yield. Nonedible deductions or carcass trims are determined by postmortem cull sow inspection before the carcass hot boning process (USDA-FSIS, 2019). These inspections include identifying carcass areas where separating infected, diseased, or nonedible portions from edible product is required. The primary reasons for trimming swine carcasses include arthritis, abscesses, nephritis, adhesions, bruises, and contamination from foreign material within the harvest facility (Keenliside, 2005; USDA-FSIS, 2019).

Sow carcasses frequently present conditions that require trimming. For example, one or more carcass trim locations were identified on 15.1% of sow carcasses, and 18.5% of carcasses had at least one meat inspection finding (Daniels and Funk, 2009; Heinonen et al., 2018).

Trimming the carcass at harvest represents economic losses for producers and harvest facilities. Although trim loss associated with carcass bruising is well documented in beef cattle (Grandin, 1980; Strappini et al., 2013; Kline, 2018), the decreased value associated with trim loss on cull sow carcasses is not well documented in the scientific literature. A Finnish study reported that cull sow carcass trim losses represented an average economic loss of 1,010.00 USD per herd or 4.50 USD per sow to pork producers (Heinonen et al., 2018). Condemnations range from just a small portion to the entire carcass. In addition, carcasses requiring extensive trimming may necessitate removing the carcass from the normal processing line, ultimately slowing down processing speed for all carcasses.

Although some carcass trimming may represent subclinical conditions (adhesions from previous infections), thermal images may identify areas of the animal’s body that could require trimming during carcass processing before harvest (Roy et al., 2019). Abscesses and sores on the body can be identified visually, but thermal imaging may be useful in determining the severity of these carcass abrasions. Determining this severity could help processors to increase throughput by reducing the time associated with trimming carcasses and better understanding when high trim loss sows will be present. This feedback could also allow producers to identify systemic farm-based concerns related to increased trim loss. Multiple studies have reported a relationship between evaluations before harvest and trim loss during harvest (van Staaveren et al., 2017; Carroll et al., 2018). This demonstrates that live animal skin and tail lesions the animal experiences before transport can be identified and assessed through carcass evaluation at harvest. Additionally, when paired with USDA meat inspection, information gathered from carcass lesion evaluation and eventual nonedible trim loss data may be used to identify on-farm management and environmental factors contributing to these issues.

Digital and infrared images have been used across multiple disciplines and species to monitor body condition, body shape, conformation, behavior, and other animal welfare-related traits (Halachmi et al., 2008; Lao et al., 2016; Stock et al., 2017; Leonard et al., 2018). Infrared thermography utilizes digital images to obtain surface temperature across the entire animal’s body (Soerensen and Pedersen, 2015). These images offer an opportunity to identify specific locations where postmortem trim loss occurs and may predict their severity. In scientific literature, very little information regarding the efficacy of thermal imaging technology to detect body lesions on the live sow and their association with carcass trim losses exists. Therefore, the objective was to test the hypothesis that infrared images of live animals have utility in predicting carcass yield loss because of mandatory trimming of carcasses from cull sows.

Materials and Methods

Animals used in this study were under USDA-FSIS inspector supervision, and only digital images were collected on the live animals immediately before harvest. Hence, it was determined that Animal Use and Care Committee approval for this project was not needed after discussion with Iowa State University Animal Use and Care Committee.

Animal description and thermal image acquisition

The project utilized trim loss and digital images from 80 sow carcasses selected from cull sows normally presented at a Midwest cull sow abattoir. Cull sow trim loss and thermal images were collected over multiple designated sampling days (n = 6) and were designed to include seasonal effects (summer and winter). Collection days occurred when the harvest facility procured “lean sows.” Lean sows tend to be more variable in body condition, health status, and overall well-being when compared with the sows typically harvested at this abattoir. “Thin” or “lean” sows are often observed to be in poor body condition (body condition score [BCS] 2) or a potentially comprised welfare state. They may have more bruising, abscesses, injuries, or carcass trimming locations when compared with the sows normally harvested at this cull sow abattoir. Test animals were selected from the cull sows present in lairage. Test animals were selected for evaluation based on certain criteria that could indicate that carcass trimming might be required. Cull sow selection was based on defect criteria classified into 5 categories. These live evaluation defect categories were (1) the presence of abscesses/sores (n = 26), (2) sows that had poor body condition (BCS 2, n = 6), (3) the presence of mammary infections (n = 3), (4) multiple issues that might require carcass trimming based on visual appraisal concerns (n = 10), and (5) no visual appraisal concerns (n = 35). The selected live sows were identified by placing a small paint mark on the sow’s back just before harvest to indicate that the sow’s carcass would be followed during harvest. The thermal images for that sow were recorded.

Thermal images were captured using a FLIR A65, model number FLIR A65, field of view 90°, 30 Hz, version 2016 (Teledyne FLIR, Wilsonville, OR) equipped with a focal plane array detector with a resolution of 640 × 512 pixels and a spectral range of 7.5 to 13 μm. The camera was mounted in a perpendicular position on the lairage area ceiling rafter (3.0 m) above the entrance to the restrainer/conveyor where the animals were immobilized (Figure 1). This camera was best angled and positioned to capture the dorsal area from each sow. Five to six seconds of video images were recorded, corresponding to the sow taking approximately 5 to 6 steps forward in the harvest line.

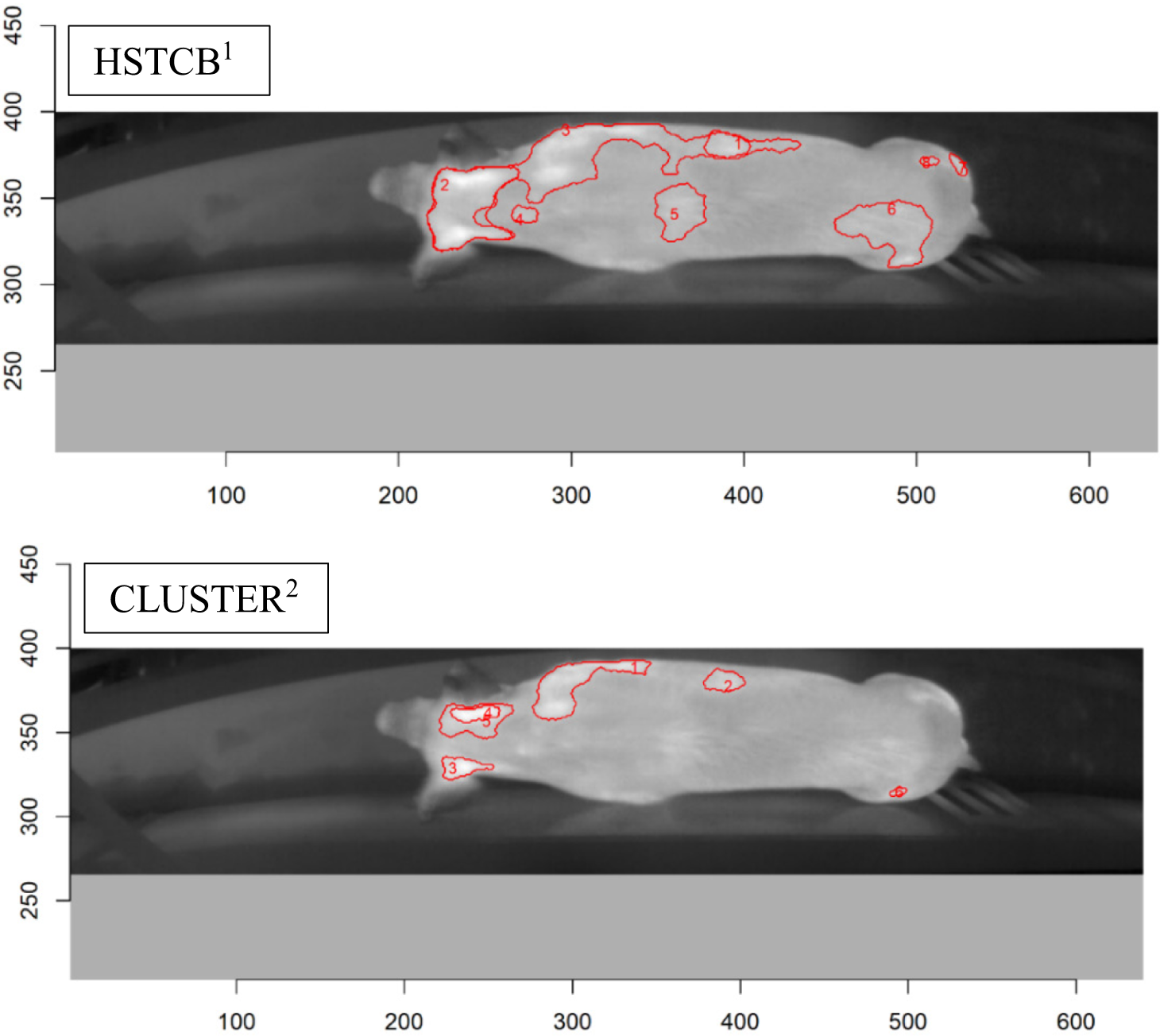

Hotspots on the live cull sow were defined using temperature difference criteria1 using assigned clustering algorithm value.2 1Hotspot surface temperature changes associated with bruising (HSTCB): seed pixel identification: 3°F above median temperature for sow image; minimum hotspot size: 1 pixel; temperature range for pixels included in each hotspot: ±2°F. 2CLUSTER: seed pixel identification: minimum value for DIFF > 4 (DIFF =|CLUSTERMEDIANi – CLUSTERMEDIAN(i+1)|j); minimum size for hotspot: 1 pixel; temperature range for pixels included in each hotspot: 90th percentile for cluster centroids for that sow’s image. 3Thermal images were recorded using a FLIR A65, model number FLIR A65, field of view 90°, 30 Hz, version 2016 (Teledyne FLIR). Each video capture was 5 to 7 s long and showed the sow taking approximately 5 to 6 steps. 5Individual pixels are numbered by the x and y axis; therefore, the d and y scales represent the location of each specific pixel, i.e., the pixel located at x = 300 and y = 360 is located in the anterior portion of the sow’s dorsal angle, and for this capture, that pixel contains the sow image.

Trim loss collection

After electrical stunning, the sow was exsanguinated, and hide was removed through a hide pulling process. The carcass of interest was identified using a large blue ear tag marked “test” attached to the sow’s underline area. This tag remained on the sow carcass of interest through the processing line. Before reaching the trimming station, the carcasses were eviscerated and split. Personnel assessing the carcasses and trimming areas of concern from each carcass were harvest facility employees with extensive training and experience in identifying and removing carcass areas unsuitable for human consumption. These carcass areas must be removed for the trimmed carcass to pass USDA inspection (USDA-FSIS, 2019). Harvest facility personnel who trimmed carcasses were positioned at 6 separate locations. The first 2 harvest facility personnel were positioned on an elevated surface and focused on assessing and trimming the posterior portion of the vertically suspended split carcass. Following posterior trim removal, 3 harvest facility personnel focused on assessing and identifying anterior areas where carcass trimming might be required. A facility employee was positioned on one side of the carcass to perform carcass trimming on all areas of the anterior portion of each half of the carcass.

In contrast, a third harvest facility worker was positioned on the opposite side. Because sow carcasses were hung vertically and suspended on gambrels, the carcasses could be rotated in clockwise and counterclockwise directions to allow harvest facility personnel to access all anterior portions of the carcass and trim areas of concern. The final carcass trim location was located at the US Department of Agriculture (USDA) inspection stand, where the carcass was assessed, and any additional carcass trimming occurred as directed by the USDA inspector. Portions of each trimmed carcass were pooled by sow and weighed to the nearest tenth of a kilogram on a platform scale (model: IGB; Ishida, Kyoto, Japan) and recorded as final trim weight (FTW). After trimming, the split and trimmed sow carcasses were weighed individually to the nearest kilogram using an in-line rail scale (Morrison Weighing Systems, model: custom, Milan, IL). The weight of each carcass half was summed and recorded as post-trim carcass weight (POSTCW). Pre-trim carcass weight (PRECW) was calculated using the following formula:

Additionally, percent trim (PTRIM) was back-calculated using the following formula:

Image isolation and analysis

Image preprocessing frame selection was conducted using the “data.table,” “imager,” “ggplot2,” “plotly,””, and “htmlwidgets” packages in R (R Core Team, 2020). Each thermal image contained multiple frames, representing the sow moving through the entry to the restrainer/conveyor. Each sow image was utilized to separate pixels with temperatures similar to those determined to be background (background pixels) from pixels with a temperature more like the sow’s temperature (sow pixels). Frames were manually selected based on identifying the individual frame in which the sow pixels could be fully isolated from background pixels. Once pixels containing the sow were isolated, only those pixels were retained for further analysis.

Within each sow thermal image, it was particularly interesting to identify regions where elevated temperature was present on the sow. The mean and median temperature for each sow’s thermal image was calculated. The median temperature for each sow’s image was utilized as the “normal” temperature for the sow (°C). “Hotspots” are defined within regions of interest. The hotspots represent pixel or pixel groupings that displayed an elevated temperature relative to that sow median temperature from that image. The “cluster,” “imager,” and “data.table” packages in R (R Core Team, 2020) were used to isolate hotspots from each sow image. Pixel data from each sow image were stored in a data table. Each data table contained the following information:

x: pixel location

y: pixel location

frame: the selected frame (selected using manual observation, 1 to 50)

value: the temperature for that pixel (°C)

is.bg: defines if the pixel is background or any object except for pig (TRUE or FALSE)

pigpix: defines if the pixel is a pig (TRUE or FALSE)

trp: pixel temperature relative to pig, trp = value − mean(pigpix)

tra: pixel temperature relative to ambient, tra = value − background pixel temperature

Using the data tables described, hotspots were defined using 2 separate criteria. The definition used to isolate hotspots for both criteria is defined as follows:

Seed pixel identification (SPI): the first pixel to be selected, pixel selected based on assigned temperature difference from median temperature for that sow, temperature difference assigned using 2 separate criteria

Minimum hotspot size (MIN): the smallest size to be considered a hotspot, held constant at 1 to identify regions of elevated temperature relative to sow’s normal temperature rather than singular pixels with elevated temperature relative to sow’s normal temperature

Pixel temperature range to be included in each hotspot (RANGE): the temperature difference from the SPI that will be included in a hotspot (larger ranges represent less sensitivity and larger hotspots, whereas smaller ranges represent more sensitivity and smaller hotspots)

Two separate criteria were used to define hotspot threshold values. The first criteria were assigned based on surface temperature change. Personal communications with practicing veterinarians in industry, veterinarians specializing in swine medicine (staff from the Veterinary Diagnostic and Production Animal Medicine Department at the Iowa State University College of Veterinary Medicine, Ames, IA), and a meat scientist led to establishing the initial threshold used to define a hotspot. These communications determined that a surface temperature change of 1.7°C would likely be associated with carcass bruising in that hotspot. The criteria used to identify the hotspot surface temperature changes associated with bruising (HSTCB) are as follows:

SPI: 1.7°C above normal temperature for sow image

MIN: 1 pixel

RANGE: ±1.1°C

The second method to define a hotspot utilized clustering data calculated by the kmeans function in R software (R Core Team, 2020). The kmeans function in R groups data to identify clusters using the following steps:

- 1.

Data points are grouped into clusters. These clusters are groups of pixels with similar values based on the clustering algorithm.

- 2.

Clusters are defined and then redefined until the central measure (centroid values) does not change.

- 3.

The median temperature for each cluster is calculated.

- 4.

Each identified cluster median temperature is compared.

The median cluster temperatures are compared using the following formula:

where CLUSTERMEDIANi represents the median temperature for the ith cluster and CLUSTERMEIDAN(i+1) is the median temperature for the compared (i+1)th cluster to establish DIFF for the jth sow.After CLUSTERMEDIAN comparisons were calculated, only DIFFs greater than 4 (DIFF > 4) defined a hotspot to be further evaluated. The DIFF > 4 were compared with the normal temperature and used for SPI. The second hotspot criteria were defined as follows:

CLUSTER:

SPI: minimum value for DIFF > 4

MIN: 1 pixel

RANGE: 90th percentile for cluster median values for that sow’s image

The hotspots calculated using both HSTCB and CLUSTER methods for the same sow are presented in Figure 1. The process for hotspot isolation is enumerated as follows:

- 1.

Hotspot threshold definition set (threshold definition set using HSTCB or CLUSTER criteria)

- 2.

Frame selection input (selected using manual observation, 1 to 50)

- 3.

Selected only pixels that value exceeded the temperature threshold (temperature threshold set using SPI for HSTCB and CLUSTER criteria)

- 4.

Each pixel that was selected as exceeding the temperature threshold defined using temperature threshold value presented as SPI for HSTCB and CLUSTER criteria is selected, with the pixel having the hottest temperature being selected first

- 5.

Pixel with the hottest temperature is set as a seed pixel (starting pixel) within the sow images body, and the area surrounding the seed pixel is flooded (temperature evaluated) until the hotspot threshold values are not met

- 6.

Data table converted to an image, hotspots are drawn on the image, and hotspot size, hotspot temperature data, and location are recorded and outputted into a file for hotspots

Using the identified hotspots, a HOTSPOTSIZE, a HOTSPOTMAGNITUDE, and HOTSPOTINTENSITY were calculated using the following formula:

where PIXELTEMP is the temperature for the ith pixel within the jth hotspot on the kth sow, MEDIANTEMP is the median temperature for the kth sow, and n is the number of total pixels (i) within the jth hotspot.After hotspot isolation and intensity calculations were completed, TOTALPIXELS > 0 (the total number of pixels above median temperature), TOTALPIXELS > 0.6 (the total number of pixels 0.6°C above median temperature), TOTALPIXELS > 1.1 (the total number of pixels 1.1°C above median temperature), HOTSPOTS (number of hotspots), HOTSPOTSIZE, HOTSPOTMAGNITUDE, HOTSPOTINTENSITY, and HOTSPOTLOCATION (NEITHER [represented no hotspots on the sow image or hotspots that were equally distributed], ANTERIOR, or POSTERIOR) were recorded.

Statistical analyses

Initial statistical analyses were conducted using R software (R Core Team, 2020). Descriptive statistics were evaluated. Means, medians, and quartile ranks were calculated for FTW, POSTCW, PRECW, and PTRIM (Table 1). Mean and median values were calculated for TOTALPIXELS > 0, TOTALPIXELS > 0.6, TOTALPIXELS > 1.1, HOTSPOTS, HOTSPOTSIZE, HOTSPOTMAGNITUDE, and HOTSPOTINTENSITY (Table 2). Pearson correlation coefficients between PTRIM and relevant carcass measurements and pixel traits were evaluated using the “ggscatter” function in the “ggpubr” package in R software (R Core Team, 2020). Stepwise regression utilizing bidirectional elimination and Akaike information criterion (AIC) methods were used in the “stepAIC” function from the “MASS” package in R software (R Core Team, 2020). Percent trim was used as the response variable. The continuous explanatory variables included in the model were POSTCW, TOTALPIXELS > 0, TOTALPIXELS > 0.6, TOTALPIXELS > 1.1, TOTALPIXELS > 1.6, TOTALPIXELS > 2.2, HOTSPOTSIZE, HOTSPOTMAGNITUDE, HOTSPOTINTENSITY, and mean ambient temperature (MAT; the mean ambient temperature for that location measured on that sample collection day). A general linear model (PROC GLM, SAS v. 9.4, SAS Institute, Cary, NC) was used to evaluate variables identified from the stepwise analysis (P < 0.15) to evaluate PTRIM in greater detail. All GLM models included the fixed effects: live identification category, number of hotspots, and hotspot location. All GLM models included linear covariates for POSTCW, TOTALPIXELS > 0, TOTALPIXELS > 0.6, TOTALPIXELS > 1.1, and MAT. The PTRIM prediction models evaluated after nonsignificant covariates were excluded are shown in Table 3. The final model from the GLM analyses of PTRIM having the greatest R2 value (response variable variation explained by linear model) included the fixed effects for number of hotspots, live identification category, hotspot location, and the linear covariates TOTALPIXELS > 0, TOTALPIXELS > 0.6. TOTALPIXELS > 1.1. The R2 estimate for this model was 0.71.

Descriptive statistics from cull sow carcasses involved in evaluating trim loss and carcass weight by quartile1

| Final Trim Weight (FTW)2,3 | Pre-trim Carcass Weight (PRECW)3 | Percent Trim (PTRIM)4 | Total Trim Contributed, % | |

|---|---|---|---|---|

| Q1 | 1.3 (±0.4) | 156.9 (±24.2) | 0.8 (±0.2) | 7 |

| Q2 | 2.4 (±0.6) | 148.6 (±27.6) | 1.7 (±0.3) | 13 |

| Q3 | 4.2 (±1.3) | 150.6 (±30.8) | 2.7 (±0.4) | 23 |

| Q4 | 10.3 (±8.4) | 148.9 (±31.1) | 6.7 (±4.9) | 57 |

Mean (±SD). SD = standard deviation.

PTRIM calculated for each cull sow. PTRIM = (FTW/PRECW) × 100.

Measure in kilograms.

Quartile classified using PTRIM values.

Pixel temperature data and hotspot measures using 2 different hotpot classification1 criteria from a study evaluating cull sow carcass trim loss

| Pixels with Elevated Temperature2 | Hotspot Measurements | |||||||

|---|---|---|---|---|---|---|---|---|

| >0 | >0.6 | >1.1 | HSP3 | SIZE4 | MAG5 | INT6 | ||

| HSTCB | Mean | 13,078 | 7,316 | 4,276 | 7 | 13,046 | 17 | 28,535 |

| ±SD | ±3,667 | ±3,146 | ±3,061 | ±6 | ±39,259 | ±20 | ±25,925 | |

| CLUSTER | Mean | 13,078 | 7,316 | 4,276 | 5 | 3,454 | 11 | 15,570 |

| ±SD | ±3,667 | ±3,146 | ±3,061 | ±3 | ±2,773 | ±8 | ±18,325 | |

Two hotspot classifications were used. The hotspot surface temperature changes associated with bruising (HSTCB); seed pixel identification (SPI): 1.6°C above median temperature for sow image; minimum size for hotspot: 1 pixel. Temperature range for pixels included in each hotspot: ±1.1°C. The CLUSTER criteria were applied using clustering algorithm in the kmeans function in R software (R Core Team, 2020).

>0 (the total number of pixels above median temperature), >0.6 (the total number of pixels 0.6°C above median temperature), >1.1 (the total number of pixels 1.1°C above median temperature), measured in pixels.

HSP = number of hotspots.

SIZE = Size for each hotspot, measured in pixels.

MAG = Σ(pixel temperature within hotspot − median temperature for sow image)/n, measured in °F and converted to °C using the conversion 1°C = 1.8°F.

INT = SIZE × MAG.

SD = standard deviation.

Percent trim1 (PTRIM, %) prediction model intercept and coefficient significance level2 for multiple hotspot definition criteria3

| Pixels with Elevated Temperature | Carcass and Animal Measurements | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Intercept | >0 | >0.6 | >1.1 | HSP7 | Location7 | LiveID8 | R2 | |

| 1 | S | S | S | S | S | S | S | 0.71 | |

| HSTCB4 | 2 | S | NS | S | S | NS | NS | NS | 0.22 |

| 1 | S | NS | S | S | NS | NS | NS | 0.09 | |

| CLUSTER5 | 2 | S | NS | S | S | NS | NS | NS | 0.10 |

PTRIM calculated for each cull sow. PTrim = PTRIM = (FTW/PRECW) × 100. FTW = final trim weight.

S = significant from zero (P < 0.05), NS = not significant (P > 0.05).

Two hotspot classifications were used.

The hotspot surface temperature changes associated with bruising (HSTCB): Seed pixel identification (SPI): 1.6°C above median temperature for sow image; minimum size for hotspot: 1 pixel; temperature range for pixels included in each hotspot: ±1.1°C.

The CLUSTER criteria were applied using clustering algorithm in the kmeans function in R software (R Core Team, 2020).

>0 (the total number of pixels above median temperature), >0.6 (the total number of pixels 0.6°C above median temperature), >1.1 (the total number of pixels 1.1°C above median temperature), measured in pixels.

HSP, number of hotspots

Live evaluation categories were (1) presence of abscesses/sores (n = 26), (2) sows that had poor body condition (n = 6), (3) presence of mammary infections (n = 3), (4) multiple issues that might require carcass trimming based on visual appraisal concerns (n = 10), (5) no visual appraisal concerns (n = 35).

Results

Simple means and standard deviations (SD) are presented by PTRIM quartile and are depicted in Table 1. When PTRIM was used to classify sows into quartiles, it was observed that sows categorized in the 4th quartile accounted for over half of the total carcass trim from all carcasses from the present study. Pixel measurement means (±SD) associated with the hotspot data are shown in Table 2. The CLUSTER hotspot criteria identified fewer hotspots, the lower SD for the number of hotspots observed, lower HOTSPOTMAGNITUDE, lower HOTSPOTINTENSITY, and lower HOTSPOTSIZE from sow’s thermal images.

The Pearson correlation coefficients between various traits and PTRIM are reported in Table 4. Using measurements defined by the HSTCB criteria, the correlation between PTRIM and the number of hotspots and HOTSPOTMAGNITUDE were significant from zero (P < 0.01) and negative. The remainder of the associations between the traits evaluated were not different from zero (P > 0.05). Similarly, using hotspot measurements defined by the CLUSTER criteria, the correlation between PTRIM and HOTSPOTMAGNITUDE was negative and significant from zero (P < 0.05). No other correlations from this group were different from zero (P > 0.05) (Table 4).

Pearson correlation coefficients between percent trim (PTRIM)2 and carcass weight (POSTCW)3, pixels with elevated temperature4, and hotspot measurements5

| Pixels with Elevated Temperature | Hotspot Measurements | |||||||

|---|---|---|---|---|---|---|---|---|

| POSTCW | >0 | >0.6 | >1.1 | HSP6 | SIZE7 | MAG8 | INT9 | |

| HSTCB | −0.11 | 0.17 | −0.08 | −0.07 | −0.30*** | −0.03 | −0.28*** | −0.14 |

| CLUSTER | −0.11 | 0.17 | −0.08 | −0.07 | −0.07 | 0.09 | −0.23** | −0.04 |

***P value < 0.01, **P value < 0.05, *P value ≤ 0.10.

PTrim calculated for each cull sow. PTrim = PTRIM = (FTW/PRECW) × 100.

Where split trimmed sow carcasses were weighed individually using a Morrison Weighing Systems model: custom). The 2 carcass half weights were totaled and recorded as post-trim carcass weight (POSTCW), and pooled carcass trim was recorded as final trim weight (FTW).

>0 (the total number of pixels above median temperature), >0.6 (the total number of pixels 0.6°C above median temperature), >1.1 (the total number of pixels 1.1°C above median temperature), measured in pixels.

Two hotspot classifications were used. The hotspot surface temperature changes associated with bruising (HSTCB): Seed pixel identification (SPI): 1.6°C above median temperature for sow image, Minimum size for hotspot: 1 pixel, Temperature range for pixels included in each hotspot: ±1.1°C. The CLUSTER criteria were applied using clustering algorithm in the kmeans function in R software (R Core Team, 2020).

HSP = number of hotspots.

SIZE = size for each hotspot, measured in pixels.

MAG = Σ(Pixel temperature within hotspot − median temperature for sow image)/n, measured in °F and converted to °C using the conversion 1°C = 1.8°F.

INT = SIZE × MAG.

When a fixed effect was a significant source of variation when predicting PTRIM from the GLM analysis, least-squares (LS) means were separated using a pairwise t test (PDIFF option, SAS v. 9.4). Fixed effect level LS means (±standard error) are presented in Table 5. The 4 live animal defect categories (abscess, poor condition, mammary infection, and multiple defects observed) were different (P < 0.05) from the weight of trim loss from sows within the no visual appraisal defect category. Additionally, the location of hotspots was a significant source of variation when evaluating PTRIM (P < 0.05). Finally, the LS means estimate for the “ANTERIOR” category was significantly different (P < 0.05) from POSTERIOR and NO LOCATION categories (Table 5).

Percent trim1 (PTRIM) least-squares (LS) means (±) by live defect identification category and location of hotspot from a study evaluating cull sow carcass trim

| Live Identification Category2 | Location of Hotspot3 | |||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 1 | 2 | 3 | |

| LS Mean | 3%a | 4%a | 4%a | 4%a | 2%b | 4%a | 2%b | 4%a |

| SE | ±0.4% | ±0.6% | ±1.1% | ±0.6% | ±0.3% | ±0.5% | ±0.3% | ±0.5% |

Row means with different superscripts are significantly different (P < 0.05).

PTRIM calculated for each cull sow. PTrim = PTRIM = (FTW/PRECW) × 100. FTW = final trim weight.

Live evaluation categories were (1) presence of abscesses/sores (n = 26), (2) sows that had poor body condition (n = 6), (3) presence of mammary infections (n = 3), (4) multiple issues that might require carcass trimming based on visual appraisal concerns (n = 10), (5) no visual appraisal concerns (n = 35).

Location of hotspot: NEITHER, ANTERIOR, or POSTERIOR.

SE = standard error.

Discussion

The results in this study report higher trim loss than previous studies (Daniels and Funk, 2009; Heinonen et al., 2018). Although this could be due to sow selection or FSIS inspector subjectivity, we concluded that sows were successfully identified that experienced trim loss in a larger capacity than normal. This research was unique because the trim weight was recorded for individual cull sow carcasses. Results from the present study indicate that a relatively small proportion of carcasses from cull sows contribute a relatively large proportion of carcass trim. In the present study, all the carcasses involved had at least some trim. A greater percentage of cull sow carcasses were trimmed in the present study compared with other scientific reports (Daniels and Funk, 2009; Heinonen et al., 2018). When PTRIM levels are divided into quartiles, the first quartile likely includes “normal trim” (mammary tissue or skin remaining after hide removal) that typically occurs on every carcass. In the present study, carcasses falling in the fourth quartile contributed 57% of FTW. Harvest facilities should identify the small percentage of sows that contribute relatively large carcass trim weight to identify reasons for trimming. This represents substantial economic losses for the producer. Identifying sow carcasses where extensive trimming is needed would allow harvest facilities to provide information to producers where on-farm mitigation strategies could be developed to reduce trim losses in order to improve producer gross income and processor throughput.

When assessing factors impacting PTRIM, the live identification defect category was a significant source of variation (P < 0.05). The categories “abscesses,” “poor condition,” “mammary infection,” and “multiple issues that might require carcass trimming based on visual appraisal concerns” categories had significantly (P < 0.05) more trim loss (PTRIM) when compared with the trim loss from the “no visual appraisal concerns” category. These results suggest that detecting various defect conditions, including abscesses, poor condition, visible mammary infections, or a combination of these factors, could be useful for predicting a substantial trim loss. The current results agree with previous work that reported abscesses, poor body condition, mammary infection, and multiple antemortem observances related to trim loss sources from cull sows carcasses (Knauer et al., 2007; Hovinen et al., 2008; Heinonen et al., 2018).

Hotspot location class was identified as a significant source of variation when evaluating PTRIM (P < 0.05). The “ANTERIOR” hotspot location had significantly (P < 0.05) less PTRIM when compared with both “POSTERIOR” and “NEITHER” hotspot location classes. Shoulder sores could be identified using thermal imaging in the present study. This finding agrees with previous studies where thermal imaging was used to identify shoulder lesions (Rioja-Lang et al., 2018). The relationship between shoulder lesions identified in thermal images and carcass trim is not clear because, in the present study, the ANTERIOR location had the lowest PTRIM estimate compared with other carcass locations (P < 0.05). The fact that the ANTERIOR location had significantly less (P < 0.05) than the other locations on cull sow carcasses in the present study may be explained by the skin emissivity for the ear base, neck, and shoulder from thermal images. This is supported by previous findings from research by Soerensen et al. (2014), who reported that the ear base, neck, and shoulder areas are among the most emissive areas from the pigs’ thermal image because of the increased blood flow in these areas.

The association between the number of observed hotspots and PTRIM is challenging to quantify. The hotspot number fixed effect was a significant source of variation when analyzing PTRIM (P < 0.05). The inability of the hotspots effect to accurately predict PTRIM is likely a multifactor issue. Roy et al. (2019) reported that isolated regions of interest were only somewhat effective in predicting carcass bruising, which agrees with the present findings. Methods for cull sow marketing contribute to variability in lairage, and the transport time, the ambient temperature in lairage, and debris present on the skin from cull sows all could have played roles in thermal image hotspot variation observed in the present study and agree with findings reported by Roy et al. (2019).

Conclusions

Video and thermal image research is a relatively new technology for identifying defects and associated trim loss from swine carcasses. This study suggests that further work is needed using larger data sets to more accurately identify sources that contribute to cull sow carcass trim variation. Large quantities of carcass trim can impact producers and processors economically. Identifying sows that will generate carcasses that require greater trim loss provides data on an individual level rather than a lot level. This technology also provides the opportunity to determine the location and severity of abrasions. The thermal image hotspot criteria defined in this study were somewhat unsuccessful in predicting percent trim observed on cull sow carcasses. The relationship between the number of observed hotspots and PTRIM is challenging to quantify. The study revealed a prevalence for more hotspots in the ANTERIOR or NEITHER, resulting in double the PTRIM observed when hotspots were primarily located in the ANTERIOR location. Live animal defect classification was a significant contributor to PTRIM variation. Finally, thermal imaging is a proof of concept to demonstrate the efficacy of detecting and scoring the severity and location of abrasions and injuries at different levels or times of production.

Literature Cited

Carroll, G. A., L. A. Boyle, A. Hanlon, L. Collins, K. Griffin, M. Friel, D. Armstrong, and N. E. O’Connell. 2018. What can carcass-based assessments tell us about the lifetime welfare status of pigs? Livest. Sci. 214:98–105. doi: https://doi.org/10.1016/j.livsci.2018.04.020

Daniels, C. S., and J. A. Funk. 2009. Prevalence of carcass defects in market swine at harvest. In: International Conference on the Epidemiology and Control of Biological, Chemical and Physical Hazards in Pigs and Pork. Iowa State University Press, Ames, IA. p. 121–123. doi: https://doi.org/10.31274/safepork-180809-862

Grandin, T. 1980. Bruises and carcass damage. Int. J. Stud. Anim. Prob. 1:10. https://www.wellbeingintlstudiesrepository.org/ijsap/vol1/iss2/10

Halachmi, I., P. Polak, D. J. Roberts, and M. Klopcic. 2008. Cow body shape and automation of condition scoring. J. Dairy Sci. 91:4444–4451. doi: https://doi.org/10.3168/jds.2007-0785

Heinonen, M., P. Bergman, M. Fredriksson-Ahomaa, A.-M. Virtala, C. Munsterhjelm, A. Valros, C. Oliviero, O. Peltoniemi, and O. Hälli. 2018. Sow mortality is associated with meat inspection findings. Livest. Sci. 208:90–95. doi: https://doi.org/10.1016/j.livsci.2017.12.011

Hovinen, M., J. Siivonen, S. Taponen, L. Hänninen, M. Pastell, A.-M. Aisla, and S. Pyörälä. 2008. Detection of clinical mastitis with the help of a thermal camera. J. Dairy Sci. 91:4592–4598. doi: https://doi.org/10.3168/jds.2008-1218

Keenliside, J. 2005. Preventing carcass losses. https://www.thepigsite.com/articles/preventing-carcass-losses (Accessed 15 June 2021.)

Kline, H. C. 2018. Carcass bruising location and bruise trim loss in finished steers, cows, and bulls at five commercial slaughter facilities. Ph.D. diss., Colorado State Univ., Fort Collins, CO. https://mountainscholar.org/handle/10217/193200

Knauer, M., K. J. Stalder, L. Karriker, T. J. Baas, C. Johnson, T. Serenius, L. Layman, and J. D. McKean. 2007. A descriptive survey of lesions from cull sows harvested at two Midwestern U.S. facilities. Prev. Vet. Med. 82:198–212. doi: https://doi.org/10.1016/j.prevetmed.2007.05.017

Lao, F., T. Brown-Brandl, J. P. Stinn, K. Liu, G. Teng, and H. Xin. 2016. Automatic recognition of lactating sow behaviors through depth image processing. Comput. Electron. Agr. 125:56–62. doi: https://doi.org/10.1016/j.compag.2016.04.026

Leonard, S. M., H. Xin, T. Brown-Brandl, and B. C. Ramirez. 2018. An image acquisition system for studying behaviors of sows and piglets in farrowing barns. In: 10th International Livestock Environment Symposium (ILES X), Omaha, NE, September 25–27. doi: https://doi.org/10.13031/iles.18-018

R Core Team. 2020. R: A language and environment for statistical computing. R. Foundation for Statistical Computing, Vienna, Austria. https://www.R-project.org/

Rioja-Lang, F. C., Y. M. Seddon, and J. A. Brown. 2018. Shoulder lesions in sows: A review of their causes, prevention, and treatment. J. Swine Health Prod. 26:101–107.

Roy, R. C., C. B. Riley, H. Stryhn, I. Dohoo, and M. S. Cockram. 2019. Infrared thermography for the ante mortem detection of bruising in horses following transport to a slaughter plant. Frontiers in Veterinary Science 5:344. doi: https://doi.org/10.3389/fvets.2018.00344

Soerensen, D. D., S. Clausen, J. B. Mercer, and L. J. Pedersen. 2014. Determining the emissivity of pig skin for accurate infrared thermography. Comput. Electron. Agr. 109:52–58. doi: https://doi.org/10.1016/j.compag.2014.09.003

Soerensen, D. D., and L. J. Pedersen. 2015. Infrared skin temperature measurements for monitoring health in pigs: A review. Acta Vet. Scand. 57:5. doi: https://doi.org/10.1186/s13028-015-0094-2

Stock, J. D., J. A. Calderón Díaz, C. E. Abell, T. J. Baas, M. F. Rothschild, B. E. Mote, and K. J. Stalder. 2017. Development of an objective feet and leg conformation evaluation method using digital imagery in swine. Journal of Animal Sciences and Livestock Production 1:06. https://digitalcommons.unl.edu/animalscifacpub/1000

Strappini, A. C., J. H. M. Metz, C. Gallo, K. Frankena, R. Vargas, I. de Freslon, and B. Kemp. 2013. Bruises in culled cows: When, where and how are they inflicted? Animal 7:485–491. doi: https://doi.org/10.1017/S1751731112001863

USDA-FSIS. 2019. Animal disposition/food safety: Post-mortem inspection. https://www.fsis.usda.gov/sites/default/files/media_file/2020-08/PHVt-Post_Mortem_Inspection.pdf (Accessed 15 November 2019.)

van Staaveren, N., B. Doyle, E. G. Manzanilla, J. A. Calderón Díaz, A. Hanlon, and L. A. Boyle. 2017. Validation of carcass lesions as indicators for on-farm health and welfare of pigs. J. Anim. Sci. 95:1528–1536. doi: https://doi.org/10.2527/jas.2016.1180