Introduction

Consumers routinely select or reject meat products based on color and appearance, so suppliers of muscle food products must create and maintain the desired color attributes. Color of muscle foods revolves around myoglobin, the primary red pigment in meat. However, ultimate perceived color is affected by many factors, such as species, animal genetics and nutritional background, postmortem changes in muscle (especially the dynamics of pH and meat temperature decline), inter- and intramuscular effects, postmortem storage temperatures and time, and a whole host of processing (including antimicrobial interventions), packaging, and display and lighting variables.

Color evaluation is an essential part of meat research, product development, and troubleshooting of processing problems. When done properly, both visual and instrumental appraisals of color are powerful and useful research tools for meat scientists. However, these evaluations must be conducted using carefully designed procedures to avoid artifacts or biased data. Simply put, complete color evaluations usually cannot be done with only one scale, sampling technique, or instrumental measurement. Measurements of color and color stability are complex and often misused in routine work.

Details of measurement must be reported for the proper interpretation of data. Tapp et al. (2011) surveyed 1,068 articles and found that 73.6% of researchers failed to report aperture size, 52.4% number of scans per sample, 48.9% illuminant used, 65.7% angle of observation, and nearly 3% failed to report the type of instrument used. Up to 8.4% did not indicate the method used to calculate tristimulus values (such as Commission Internationale de l’Eclairage [CIE] L*a*b* vs. Hunter Lab), nor did they state whether universally accepted revisions of the 1976 CIE for the calculation of CIE L*a*b* (CIE, 1976) were followed. Only 24.8% of the articles calculated hue angle, and only 25.5% calculated saturation index. Similar inconsistencies likely also exist for the reporting of visual color evaluations. These guidelines should encourage more uniform reporting of pertinent experimental details and sample properties for studies involving visual and/or instrumental color evaluation.

Moreover, these guidelines provide suggestions for researchers investigating the biological basis of meat color. A thorough review of the entirety of these guidelines is strongly suggested to those new to meat color research. However, users should be able to pick and choose the background information needed to ensure that their efforts result in reliable and accurate appraisals of color. These guidelines are intended for use in planning and executing investigations involving meat color. Investigators must integrate the principles detailed in these guidelines into their experimental design to address the specific question of interest.

Myoglobin Chemistry

Fundamental myoglobin chemistry

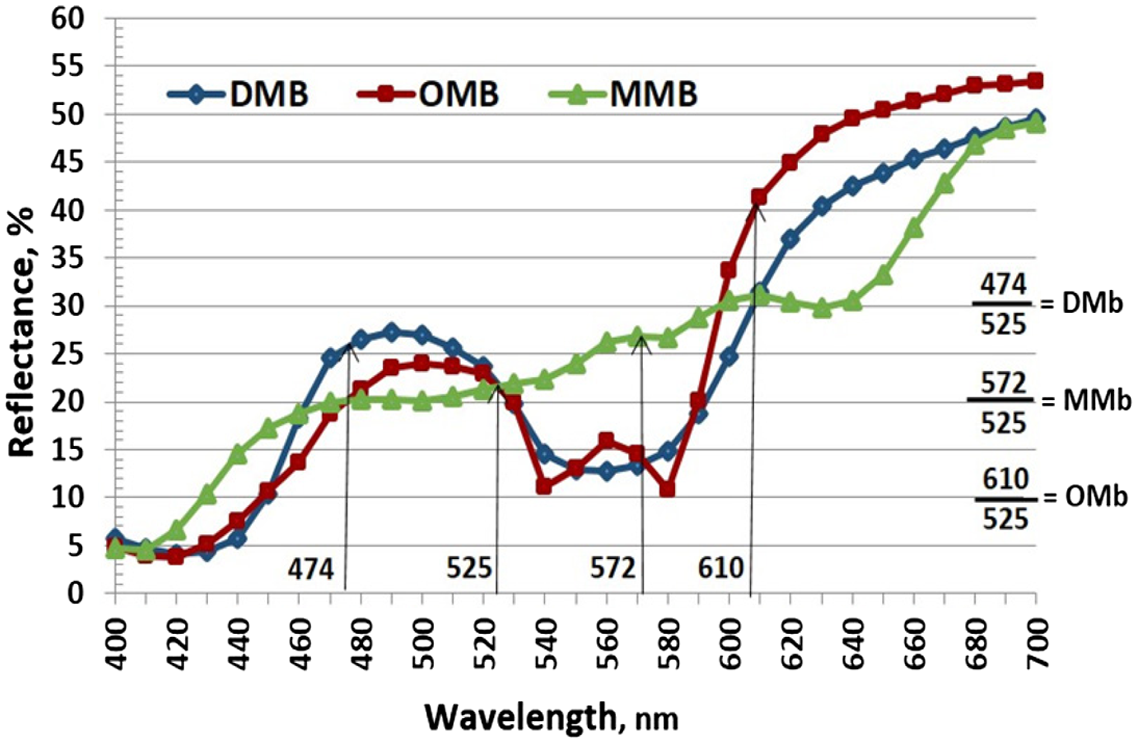

Myoglobin is the water-soluble protein responsible for meat color. Within the 8 α-helices (often labeled A–H) of myoglobin, a prosthetic heme group containing a centrally located iron atom is positioned in the protein’s hydrophobic core. Of the 6 bonds associated with this iron atom, 4 connect iron to the heme ring, the 5th attaches to the proximal histidine-93, and the 6th site is available to reversibly bind ligands including diatomic oxygen, carbon monoxide (CO), water, and nitric oxide (NO). The ligand present at the 6th coordination site and the valence state of iron determine meat color via 4 chemical forms of myoglobin: deoxymyoglobin (DMb), oxymyoglobin (OMb), carboxymyoglobin (COMb), and metmyoglobin (MMb) (see Figure 1).

Deoxymyoglobin results in a dark purplish-red or purplish-pink color typical of the interior color of fresh meat and that in vacuum packages. Deoxymyoglobin contains ferrous iron (Fe2+) with a vacant (no ligand attached) 6th coordination site. To maintain DMb, very low oxygen tension (< 1.4 mm Hg) within vacuum packages or the interior of muscle is necessary. Oxygenation of DMb forms a bright red color via the formation of OMb, which has diatomic oxygen attached to the 6th coordination site of Fe2+. The oxygen ligand also interacts with the distal histidine-64, producing a more compact protein structure than DMb, which has no ligand present to link iron to the distal histidine. Carboxymyoglobin formation occurs when CO attaches to the vacant 6th position of DMb, producing a stable bright red color when the environment is devoid of oxygen. Atmospheres containing oxygen (albeit concentration dependent) will result in the conversion of COMb to either OMb or MMb. Metmyoglobin is the oxidized form of myoglobin with a ferric iron (Fe3+), resulting in a tan- to brown-colored form of myoglobin. Typically, MMb forms easily at 1% to 3% oxygen, which is equivalent to oxygen partial pressures of 1 to 25 torr (see “Partial Pressure of Gases in Meat Packages” in Appendix E). Water is the ligand at the 6th position of the iron in MMb.

Dynamics of myoglobin redox form interconversions

Myoglobin oxygenation or blooming (reaction 1 in Figure 1) depends on time, temperature, pH, and competition for oxygen by mitochondria. More specifically, the competition for oxygen between myoglobin and mitochondria determines oxygen penetration beneath the meat’s surface, which significantly affects the intensity of surface color. Partial pressures of oxygen greater than that in the atmosphere will facilitate a thicker OMb layer on and just below the meat’s surface. Under anaerobic conditions, DMb will also turn red (Figure 1, reaction 5) when exposed to CO; this reaction is reversible, but the forward reaction is favored.

Deoxygenation of OMb to DMb (Figure 1, reaction 3) is favored under low-oxygen partial pressures that occur when dissolved oxygen in muscle tissue is consumed by various reactions, including mitochondrial respiration. Re-blooming may occur immediately if oxygen re-unites with the DMb. However, DMb is susceptible to oxidation by oxygen radicals and reactive oxygen species (mainly hydrogen peroxide), forming MMb (Figure 1, upper right branch of reaction 3). This reaction occurs most rapidly at oxygen partial pressures of 1 to 25 torr because there is not sufficient oxygen to bind to available DMb. As a result, DMb will react with hydrogen peroxide and oxidize to MMb. Conversely, at oxygen partial pressures that promote DMb oxygenation, there is less DMb available to react with hydrogen peroxide. Thus, greater OMb levels will minimize MMb formation.

Thermodynamically, OMb is resistant to oxidation to MMb; thus, reaction 2 (Figure 1) is unlikely. The rapid browning that often occurs in meat seems to contradict this chemistry, but the origin of MMb is through the deoxygenation reaction of OMb to DMb, which can be rapidly oxidized to MMb. Under aerobic conditions, metal ions (iron, copper) stimulate the formation of oxygen radicals from diatomic oxygen, leading to MMb formation. Metal chelators (such as citrate, phosphates, etc.) inhibit or delay MMb formation. Radical scavenging antioxidants (tertiary butylhydroquinone [TBHQ], butylated hydroxytoluene [BHT], butylated hydroxyanisole [BHA], vitamin E, spice extracts, and plant polyphenols) also slow MMb formation.

Oxidation of ferrous DMb to ferric MMb causes brown discoloration. MMb formation tends to initiate beneath the surface between the superficial OMb and interior DMb where oxygen partial pressure is not high enough to oxygenate all available DMb. Thus, some DMb is available to react with oxygen radicals, forming MMb. Hydrogen peroxide and oxygen radicals are continually present in aerobic conditions because they are by-products of mitochondrial metabolism and lipid oxidation. The thin subsurface layer of MMb thickens as MMb concentration increases. Gradually, the surface OMb layer becomes thinner as the underlying MMb band thickens, encroaches, and replaces the OMb layer to the point that, visually, the surface color changes from bright red to dull red to brown. Conditions that delay the appearance of subsurface MMb include low temperature, high pH, antioxidant capacity, and greater reducing activity. MMb reduction influences meat color stability by regenerating ferrous myoglobin. However, this reaction depends on oxygen scavenging, reducing enzymes, and the nicotinamide adenine dinucleotide (NADH) pool, all of which are limited and continually depleted in postmortem muscle. MMb reduction by endogenous reducing systems in meat may offer a critical strategic approach to decrease MMb formation and increase fresh meat color life.

Mitochondrial activity, enzymatic- and nonenzymatic processes can reduce MMb to DMb (Figure 1, reaction 4); this reaction is critical to meat color stability. Numerous extrinsic and intrinsic factors affect this reaction, but oxygen consumption, MMb reducing activity (MRA), and the postmortem pool of NADH are significant variables in the extension of the color life of meat. Research indicates that the addition of various glycolytic and Krebs cycle intermediates such as glutamate, lactate, malate, pyruvate, and succinate can regenerate reducing equivalents and extend fresh meat color stability.

Visual, practical meat color versus actual pigment chemistry

In the meat industry, meat color chemistry can be confusing because visual observations of color change differ somewhat from the chemical pathways described earlier. Industry practitioners and meat scientists conducting research with meat and meat products usually see brown MMb forming directly from bright red OMb. Thus, it is sometimes difficult to put the principles shown in Figure 1 into practice, especially when troubleshooting meat color problems. In particular, Figure 1 shows that purple DMb is an intermediate in the conversion of OMb to MMb, but this is seldom observed in practice. Rather, Figure 2, reaction 2a shows that bright red OMb changes directly to brown MMb, without any visual development of purple DMb.

Schematic of the visual, practical interconversions of myoglobin redox forms in fresh meat. Myoglobin interconversions in a purified and meat system are different (Figure 1). Figure 2 explains myoglobin interconversion in an in situ meat system and may not be applicable to a purified system. Courtesy of M. C. Hunt, Kansas State University.

Reconciling the apparent contradiction between the chemical and visual pathways

The answer lies in careful observation of the changes occurring at and immediately beneath the meat’s surface. Fresh-cut meat surfaces are purple (DMb) because of the absence of oxygen. After several minutes in air, the meat surface is bright red (OMb; Figure 2, reaction 1). A cross-section of the meat would reveal that the red surface layer is < 1 mm thick, and the deeper muscle tissue is purple. After several hours, the red surface layer is typically 2 to 3 mm thick (thicker in muscles with low oxygen consumption and thinner in muscles with high oxygen consumption). After 1 to 3 d at 2°C to 4°C, a thin layer of brown MMb becomes apparent, just below the OMb layer. As previously explained, the brown layer develops because of reaction of DMb with oxygen radicals forming MMb. Because MMb is usually formed more rapidly (Figure 1, reaction 3) than the reverse reaction (Figure 2, reaction 2b; MMb conversion to DMb), MMb concentration increases with time. By several days of storage or display, the thickness of the surface OMb layer decreases as the MMb layer progressively moves toward the surface, which makes the OMb layer appear duller and dimmer. Eventually, the MRA of the tissue in the OMb layer is depleted and the MMb layer reaches the surface with total discoloration.

How is it known that deoxymyoglobin was formed as an intermediate in the browning reaction?

Metmyoglobin formation is much slower in 70% to 80% oxygen compared with atmospheric conditions (21% oxygen). Thus, the OMb cannot react with oxygen radicals to form MMb. In addition, there is a dynamic disassociation equilibrium in which OMb is continually converted to DMb + oxygen and vice versa. In the brown MMb layer where oxygen levels are low, some DMb has re-associated with oxygen radicals instead of oxygen, causing fairly rapid oxidation of DMb to MMb.

If deoxymyoglobin is formed, why does the surface color change directly from red to brown, with no purple intermediate?

The answer lies in the fact that purple DMb formation is obscured by the overlying red OMb layer during the first 1 to 3 d of storage or display and later by the increasing thickness of the MMb layer. Furthermore, in the surface OMb layer, the small amounts of DMb formed by equilibrium dissociation are rapidly converted back to OMb, owing to the excess of oxygen near the surface.

How does metmyoglobin change to purple deoxymyoglobin after sufficient vacuum (anaerobic) storage?

First, the thin brown MMb layer develops because of vacuum removal of some, but not all, oxygen. The low oxygen level at the meat surface favors browning, as previously explained. The purple DMb becomes apparent only after the overlying red OMb and brown MMb levels disappear. Oxymyoglobin levels go to near 0 mainly because of muscle mitochondrial oxygen consumption. MMb levels go to near 0 owing to somewhat slow enzymatic or nonenzymatic MMb reduction to DMb. It is well known that color-stable muscles do this more easily than color-labile muscles, which may only partially convert MMb to DMb.

The temperature optima for OMb preservation or DMb formation lead to different recommendations for storage temperature. For instance, OMb is most stable at low temperature (−1°C to 2°C). However, DMb will develop more quickly in the OMb–MMb interface area of vacuum-packaged meats if held at warmer temperatures (3°C to 4°C or higher) for several hours, to stimulate mitochondrial oxygen consumption and MMb reduction reactions 2a and 2b of Figure 2.

Meat packaged in aerobic modified atmospheres will also turn brown but at a variable rate depending on muscle, postmortem age (especially at warmer temperatures), and other retail display conditions. Bacterial growth can also affect reactions 2b and 3. Reactions 3 and 4 proceed as described previously.

Why confuse the issue with two fresh color triangles?

In practice, separating the visual conversion of OMb to DMb as shown in Figure 2 with an intermediate formation of MMb allows industry to manage color problems more easily because it separates the required chemistry into 2 critical, practical reactions in which MMb formation (Figure 2, reaction 2a) always seems to occur but MMb reduction (Figure 2, reaction 2b) is often problematic and requires special attention to processing practices.

Factors affecting fresh meat color

The literature clearly documents that many factors affect meat color. Several component traits contribute directly to meat color and the biochemical reactions resulting in changes in meat color. Rate and extent of postmortem pH decline, amount of protein denaturation during conversion of muscle to meat, antioxidant concentrations, biochemical intermediates available to modulate meat color, and the quantity of unsaturated fatty acids directly contribute to multiple mechanisms affecting meat’s use of oxygen and meat’s ability to reduce MMb.

Intrinsic muscle characteristics—such as pH, muscle type, muscle fiber type composition, myoglobin concentration, disruption of various subcellular components related to meat color chemistry, and water-holding capacity—influence the component traits driving differences in lean color and color change during storage or display. Animal genetics interact with environmental factors to determine these muscle characteristics and how they respond to postmortem management. Antemortem factors affecting these muscle characteristics include gender, age, diet energy density, time-on-feed, seasonality, and antemortem stress.

Of the numerous postmortem factors affecting color chemistry, muscle temperature is of the greatest concern. Factors affecting temperature decline during chilling include carcass weight, method of immobilization, chilling rate, and scalding and singeing. Parameters for carcass electrical stimulation have a tremendous impact on the extent of pH decline at a given muscle temperature and therefore are of great importance. Moreover, controlling temperatures during storage, processing, and transport is critical.

Application of antimicrobial interventions, postmortem processing and packaging methods, time and temperature of storage, extent of exposure to oxygen and the number of times meat goes through the color cycle, and postmortem age of the product usually influence meat color by directly and indirectly influencing the component traits of meat color. As many of these factors as possible should be controlled during designing and reporting of meat color research.

Muscle metabolism and meat color

Cellular biochemistry differs across muscles within a carcass, influencing postmortem metabolism of skeletal muscles. McKenna et al. (2005) examined various biochemical mechanisms influencing color stability in 19 beef muscles, whereas other researchers (Mancini et al., 2009; Suman et al., 2009) reported that color-stable and color-labile beef muscles respond differently to modified atmosphere packaging (MAP) systems and to browning induced by cooking.

The role of mitochondria in meat color has received significant attention, and the mechanisms through which mitochondria influence myoglobin redox stability have been investigated. The influences of vitamin E (Tang et al., 2005a), lipid oxidation (Tang et al., 2005a), oxygen consumption rate (OCR; Tang et al., 2005b; Mohan et al., 2010c), and metabolites (Tang et al., 2005c; Ramanathan et al., 2009; Mohan et al., 2010b) on the interactions between mitochondria and myoglobin suggest that both the electron transport chain and reductase enzymes in the outer membrane can reduce MMb and therefore are involved in color stability.

Cooked meat color

The process of cooking denatures myoglobin, which is responsible for the characteristic dull brown color of cooked meat products. However, the denaturation temperature for different redox forms of myoglobin is not constant; therefore, the relative brown color of cooked product interiors is not necessarily a reliable indicator of degree of doneness. Myoglobin’s denaturation temperature depends on the protein’s redox status. More specifically, the relative resistance of myoglobin to heat-induced denaturation is as follows: COMb > DMb > OMb > MMb (Ballard, 2004).

Premature browning (see “Ground Beef Patty Cooked Color Guide” in Appendix B(A)) is a phenomenon in cooked beef in which myoglobin denaturation—and, as a result, cooked appearance—occurs at a temperature too low to inactivate pathogens. Killinger et al. (2000) reported that the incidence of premature browning in ground beef purchased from local retail stores was about 47%. Both intrinsic (myoglobin redox state, muscle source, and antioxidants) and extrinsic (packaging, storage, and cooking from a frozen state) factors influence the susceptibility of beef to premature browning.

Persistent pinking (the opposite of premature browning) is a cooked-color defect in which myoglobin is more stable and resistant to thermal denaturation, resulting in an undercooked appearance. The most common cause of persistent pinking is elevated pH. Slight pinking starts at pH 5.9 and becomes progressively more pink above pH 6. Prevention of pH-induced pinking can be minimized by reducing the pH (logical, but not easily done), increasing the endpoint temperature, or both.

Meat with a normal pH that contains COMb will be more heat stable, increasing the endpoint doneness by one-half to two-thirds of a degree of doneness. Persistent pinking also can be caused by several sources of nitrogen oxides, including small amounts of NO3− or NO2− in other food sources, spices, or water added to meat. Incomplete combustion products of gas-fired ovens also may cause surface pinking. These forms of pinking can be minimized or eliminated by removal of the causative agent and/or increasing the endpoint temperature.

Cured meat color

A significant portion of cured meat color chemistry involves the same factors that affect myoglobin chemistry of fresh meat. However, the reactions resulting in the pink, heat-stable, cured meat pigment (nitrosyl-hemochrome) are more complex owing to hundreds of curing protocols practiced globally. Nitrate and/or NO2− are added to many meat-curing formulations in solid or liquid form.

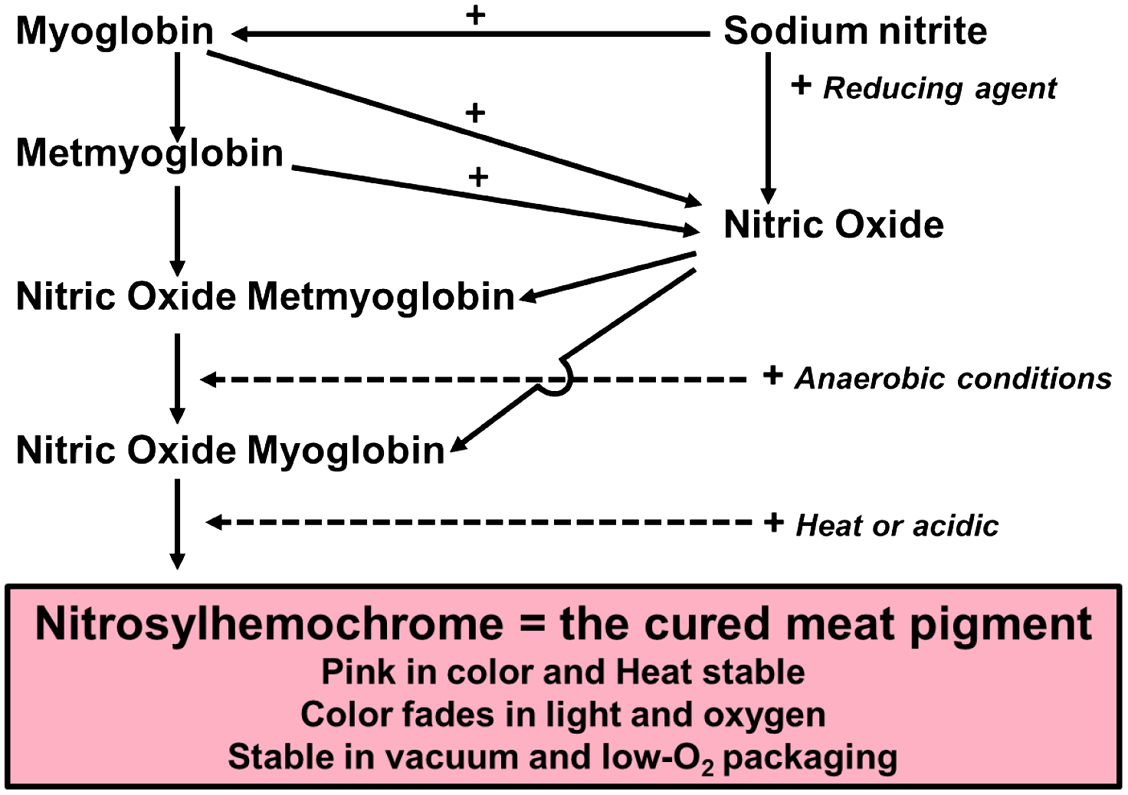

Nitrite addition (Figure 3) causes the characteristic pink color associated with cured products. Added NO2− binds with the heme moiety of DMb, with rapid reduction of the bound NO2− to NO, and simultaneous heme oxidation to the ferric form (Figure 3). Visual indication for this reaction is given by the rapid browning that occurs when NO2−-containing brines are added to fresh meats. Under anaerobic conditions, brown NO-MMb is then reduced to red NO-myoglobin by added reductants such as erythorbate, or more slowly by endogenous reductants, in combination with MMb reductase enzymes. Some studies indicate that in brines containing NO2− and reductants, the NO2− also rapidly reacts with reductants to generate NO, which in turn binds MMb, forming NO-MMb.

Reactions leading to formation of nitrosyl-hemochrome. Note: The solid arrows indicate reactions, and the dotted arrows indicate conditions that favor the reaction. The “+” indicates a reaction between the 2 connected “reactants,” and the product is shown by the next arrow. Examples: myoglobin + NaNO2 can form MMb (this is a step in some MRA assays); metmyoglobin + NO can form NO-MMb; myoglobin + NO can form NO-myoglobin, or with anaerobic conditions NO-MMb is reduced to NO-myoglobin; heat or acid conditions favor globin protein denaturation, and NO-myoglobin is converted to nitrosyl-hemochrome. Courtesy of Drs. M. C. Hunt, Kansas State University, and D. P. Cornforth, Utah State University. MMb, metmyoglobin; MRA, MMb reducing activity.

One precaution in the handling of brines containing NO2− and erythorbate is to keep temperature below 10°C. At higher temperatures, erythorbate will rapidly reduce NO2− to NO gas, which escapes before brine injection, resulting in poor or no cured color development in the cooked product.

Denaturation of NO-myoglobin and NO-hemoglobin during cooking or fermentation exposes the centrally located porphyrin ring, resulting in the pink cured meat pigment nitrosyl-hemochrome, due to the interaction between ferrous iron and NO. The pink color will fade to gray when exposed to light and oxygen.

To cure meat without directly adding NO3−, a variety of non-meat ingredients that naturally contain sufficient NO3− can be added to meat formulations to form a cured color. During processing, one or more non-meat ingredients such as celery juice, powder or concentrates and/or isolates (or numerous other vegetable products, ascorbic acid, cherry powder, spices, etc.) can be reduced so that the NO2− will eventually form nitric acid myoglobin, which will be converted to nitrosyl-hemochrome with heat or acidic conditions. This “cured meat pigment” is pinkish/red, heat stable, and color stable with vacuum conditions. The color fades in air and light (Figure 3). Cured color and flavor stability usually increases with greater amounts of generated NO2−. Meat products cured by this method often are perceived by consumers as being more natural and wholesome. Some regulatory agencies allow these products to be labelled “NO2−-free.”

FreshCase™ (Curwood, Inc.) produces a packaging film embedded with NO2− for use with vacuum-packaged fresh meat (Figure 4). Once packaged, the NO2− is released and forms the uncooked, red pigment (NO-myoglobin, Figure 3) on the surface of the meat. This results in vacuum packages of fresh meat with a reddish surface color rather than the typical purple color of vacuum-packaged fresh meat. Fresh meat packaged with the NO2−-embedded film has greater color stability and shelf life than other fresh meat formats with OMb on the surface. Regardless of the curing methodology used, it is essential that myoglobin be exposed to NO to create several different nitrosyl heme pigments. Thus, optimizing formulations for various extrinsic and intrinsic factors important to fresh meat color chemistry are also essential to achieve desired final product specifications, consistency, quality, and safety of a large variety of processed meats.

What is the actual curing (nitrosating) agent, nitrite or nitric oxide?

There is some disagreement on this point among various literature sources. Recent evidence points to NO2− as the compound that first reacts with heme iron. This makes sense because NO2− is water soluble, with small enough molecular diameter to penetrate the heme cleft, and its negative charge would provide electrostatic attraction to the positively charged heme iron. Nitric oxide gas, on the other hand, is not very water soluble, and tends to leave the brine. Some studies with pure myoglobin solutions, or with meat batters, have shown cured color development after exposure to NO gas. But, NO may not have directly reacted with heme iron in these experiments. Under aerobic conditions, NO reacts with oxygen to form nitrogen dioxide (NO2) gas, which in turn reacts rapidly with water to form the NO2− ion. Thus, even in the presence of NO gas, NO2− is likely the active meat-curing agent. Historically, NO3− salts were used for meat curing but were reduced to NO2− by bacterial action for curing to occur. Cured color development may also occur on grilled or smoked meat, owing to the presence of nitrogen dioxide, which forms NO2− ions when moist meat surfaces interact with combustion gases.

Is cured meat pigment mono-nitrosyl-hemochrome or di-nitrosyl-hemochrome?

Stoichiometric studies found that a ratio of 2 mol of NO2− was needed for formation of 1 mol of cured meat pigment, indicating that the pigment was di-nitrosyl-hemochrome. However, the only study of cured pigment structure using mass spectroscopy found that the molecular ion fragment had an atomic mass of 646 units, rather than 676 atomic mass units predicted for di-nitrosyl-hemochrome. This result strongly indicated that cured meat pigment is mono-nitrosyl-hemochrome. Further work indicated that another NO was bound to the globin portion of the pigment. Thus, 2 mol of NO binds to myoglobin, but only 1 mol of NO binds to the color-inducing heme group.

Iridescence

Iridescence results in a shiny, rainbow-like appearance on the surface of cooked meat products. This kaleidoscope-like appearance is often associated with green, red, orange, and yellow colors caused by product surface microstructure and light diffraction, not the myoglobin redox state. More specifically, structural uniformity on the surface of meat products results in light diffraction conducive to iridescence, whereas disruption of surface microstructure reflects light in a relatively irregular pattern that limits iridescence (Lawrence et al., 2002a, 2002b).

Physics of Color and Light

Perceiving an object and identifying the color of that object involves a complex set of circumstances consisting of the object, its surroundings, and the detector that perceives the object and translates the stimuli into a perception of color. That detector can be the human eye or instrumentation such as a colorimeter or spectrophotometer.

For human sensory response and detection of color, the eye and brain work synergistically to detect and process stimuli to discern color. The eye is composed of the cornea, pupil, iris, and lens, which together form the anterior chamber of the eye. The lens separates the anterior chamber from the posterior chamber (vitreous), which contains the retina and optic nerve. The eye operates much like a camera. Light passes through the pupil where the lens focuses the light onto the retina. The iris works much like a shutter in a camera, opening to allow more light to come into the eye in low light conditions and constricting to restrict light in bright conditions.

The retina is the organelle that senses light. The light detectors of the retina are the rods and cones. Rods are not color sensitive but respond to the visual sensation of light from black through gray to white. The cones are color sensitive to visual sensations of the visible light. The cones can be divided into 3 types based on the portion of the light spectrum to which they have peak responses, blue, green, or red. Therefore, when light penetrates the eye, the rods detect lightness/darkness stimuli, and the cones detect light spectra in the blue, green, and red spectra. The detection of blue, green, and red spectra is referred to as the trichromatic function of the eye. The detection of these stimuli is then transmitted from the optic nerve to the brain, where the information is processed, and a visual perception of the object is developed.

Therefore, the complex interaction of eye and brain is what develops color perception. This is subject to numerous factors that can skew the perception of color, particularly the detection and processing of color. To determine color, a detector capable of capturing this information is necessary. However, not all eyes have the same ability to detect light sensations and process them into color perceptions. As a notable example, some humans suffer from red-green color blindness. Although the light spectrum permits the sensation of color, the detector (eye) cannot detect, and the brain cannot process these stimuli appropriately. Therefore, any color measurement requires a functioning detector. In the case of human color perception, charts for detection of color blindness are available on the internet.

Note that the eye, or some other mechanical device, does not “see” color, it simply captures wavelengths of light reflected from an object, such as meat, and in the case of the eye, relays this sensory input to the brain for interpretation. The color of meat or other objects is the interaction between light, vision (the detector), and the object being viewed. Without light, there is no color and no vision. Visible light is a part of the electromagnetic spectrum, which is defined by the wavelengths of energy and includes broadcast, radar, infrared, ultraviolet (UV), x-rays, gamma rays, and cosmic rays. However, humans can only detect light in the visual spectrum, which ranges from 390 to 750 nm. In this narrow range of the electromagnetic spectrum, the eye has the ability and the brain the capacity to separate wavelengths into color groups. For instance, red color is associated with light of approximately 650- to 700-nm wavelengths. Green color is associated with approximately 490 to 575 nm, and blue is associated with wavelengths between 455 and 490 nm (Figure 5).

For color to be visually detected, light must reflect off the object being viewed and return to the eye. To have color development, the light illuminating the object must contain the spectral range to allow reflectance of corresponding wavelengths that the eye can detect and the brain interpret as color. Therefore, with full visual spectral light comes the possibility for an infinite number of colors to be developed. When light strikes meat, it will be absorbed, reflected, or scattered. The wavelengths of light that are absorbed are not perceptible to the eye because they are retained by the object (e.g., meat; Figure 6). The reflected light is perceived by the eye, captured, and transmitted to the brain. Because the eye is trichromatic, the brain interprets the intensity of the blue, green, and red stimuli that the eye captures and interprets it as a color. So to discern meat color, the source of light must contain the wavelengths capable of reflecting off meat surfaces or color will not be perceptible to the eye or instrumental detector. For sensory and instrumental evaluation of meat, the light source must be standardized. Overall, for humans to see the true color of an object, a balanced light source should be used. In summary, using a light source, such as the incandescent lamp (Figures 6 and 7), will make fresh meat appear more bright red than a 5,000-K fluorescent lamp with a lower red spectral output (Figure 6).

Spectra reflectance of a slice of beef meat (top). Relative reflectance of the different wavelengths (bottom). Please note that the observer sees only the wavelengths/colors reflected from the surface and not the wavelengths absorbed by the surface/meat. Courtesy of Dr. Shai Barbut, University of Guelph.

Examples of spectral power distribution from an incandescent light bulb (left) and fluorescent bulb (right) (https://en.wikipedia.org/wiki/Spectral_power_distribution#/media/File:Spectral_Power_Distributions.png; http://creativecommons.org/licenses/by-sa/3.0/deed.en).

In addition to the physics involved in light detection and color generation and perception, numerous physical conditions impact the color of meat. The following discussion does not focus on the pigment condition or chemistry of meat but how color can be perceived differently for the same cut under different conditions. Conditions that can influence color perception are the light source (illuminant), observer differences, size differences in cut or object, smoothness of the surface (e.g., using sharp or dull knife to cut meat), background differences, and directional differences.

Wavelengths of light reflected from meat develop the perception of color, so the light source becomes an issue in the development and perception of color. Light sources or illuminants come in many different types: sunlight, fluorescent light, and tungsten light, among many others. Even within types of illuminants, lighting sources can differ greatly. Each light source contains a different spectral light composition. Figure 6 illustrates the output of 2 light sources. A so-called balanced light source will have an equal/balanced output of different wavelengths (e.g., sunlight). For this reason, meat may look one way in a retail display case but lose its favorable appearance under store lighting (many stores use fluorescent light in their display coolers because the light bulb produces very little heat and is more efficient than an incandescent light bulb, which loses >70% of its energy as heat). Therefore, when choosing a light source for research, the type of lighting and the light source must remain constant for proper comparison of color. One common light source for viewing meat is deluxe warm white fluorescent lighting. Along with light source, the intensity of light is also important in perceiving color; neither too bright nor too dim is good when viewing meat. Approximately 1,630 lux is commonly used to compare meat samples for color. Figure 8 shows the actual wavelengths reflected from 3 fresh meat cuts illuminated with a cool white fluorescent bulb. These spectra are what would be detected and evaluated by consumers’ eyes. This light bulb has major peaks in the indigo, green, and orange areas (similar to the 5,000-K lamp in Figure 6) but very low output in the red area; thus, a consumer panel perceived the beef, pork, and chicken cuts as brown. In contrast, when the panel was presented the same meat under incandescent lighting (reflectance spectra similar to those shown in Figure 6 and the 2,800-K lamp in Figure 7), the consumer panel scores were pinker/redder.

Relative luminance of fresh meat cuts positioned under cool white fluorescent light bulb. Note that this specific light bulb has major peaks in the indigo, green, and orange colors. The minimal light output toward the end of the visible spectrum results in poor appreciation of the red color of the beef and pork meat cuts. Source: Barbut, S. Effect of illumination source on the appearance of fresh meat cuts. Meat Sci. 2001;59:187–191 (reprinted with permission from Elsevier).

Observer differences are another condition that can affect color perception. Each individual’s eyes are slightly different in sensitivity to color vision. This is perhaps the most difficult to control of all the conditions that affect color perception. Screening for color vision perception can aid in selecting panelists capable of discerning meat color differences (see color blindness charts of Wiegand and Waloszek [2003]; note that a computer screen presentation of these charts might not be correct if the screen is not fully adjusted).

Size differences in meat cuts can also affect how color is perceived because of the amount of light reflected to the eye. For larger cuts, more light is reflected to the eye, and color is often perceived as being brighter and more vivid.

Background differences will also affect color perception. Cuts viewed against a bright background often appear to have duller color, whereas cuts viewed against a dark background often appear brighter. Care should be taken to standardize the background so that comparative color determinations can be made. Also, background color becomes important in meat photography, wherein light backgrounds can give a false impression of dull or pale color whereas dark backgrounds tend to best capture meat color vividness.

In addition, the angle from which the cut is viewed and the incident angle of light from the illuminant source will both affect color perception. This is particularly important when gloss occurs, which may impede ability to view the sample. Furthermore, for conditions like iridescence, the incident angle of light to the observer can render this condition either visible or invisible. Backlighting should be avoided; overhead light is preferred. When setting lights, light intensity should be standardized with a light meter.

Color perception of meat

Once light strikes the surface of meat and is reflected back to the detector (eye or instrument), the processor (brain or microprocessor) interprets color. Communicating color can be quite challenging. To facilitate color communication, tools have been developed to aid in speaking the language of color. The Munsell system, developed by American artist A. H. Munsell, uses color chips to match the color of a specimen. The CIE developed the XYZ tristimulus values (Figure 9) in 1931 and the CIE L*a*b* color space in 1976 (CIE, 1976; Figure 10). The reason the CIE L*a*b* system was developed was that the XYZ colorimetric distances between the individual colors do not correspond to perceived color differences. For example, the difference between green and greenish-yellow is relatively large, whereas the distance distinguishing blue from red is quite small. The CIE solved this problem in 1976 with the development of the three-dimensional “L, a, b” color space (or CIELAB color space). In this system, the color differences one perceives correspond to distances when measured colorimetrically. The a axis extends from green (−a) to red (+a) and the b axis from blue (−b) to yellow (+b). The brightness (L) increases from the bottom to the top of the three-dimensional model (Figure 9). In reporting colorimeter values for research, authors must note whether CIE L*a*b* values or CIE Lab values were used. (The presence or absence of the asterisks is reflective of slight mathematical differences in how each of these values is calculated.)

CIE (1931) color space (illustration of the CIE 1931 color space; https://en.wikipedia.org/wiki/International_Commission_on_Illumination#/media/File:CIExy1931.png; http://creativecommons.org/licenses/by-sa/3.0/deed.en). CIE, Commission Internationale de l’Eclairage.

Perceptible color has hue, lightness, and saturation properties. Hue is the color description as we communicate it in language (red, yellow, green, blue, etc.). Hue is determined by the specific wavelengths reflected from a meat surface back to the detector. Lightness describes the brightness or darkness of the color. Saturation refers to how vivid or dull the color is. To measure or describe color, a number of methods have been established.

The XYZ tristimulus values and the associated Yxy color space established a methodology for describing color (Figure 10). From this, the CIE x, y chromaticity diagram was developed. This representation allowed achromatic colors (pale or dull colors, lower saturation) to populate the center of the diagram, whereas the chromaticity increases toward the periphery of the diagram (more vivid colors, more saturation). Around the periphery are red, green, and blue primary colors and the corresponding wavelengths of visible light associated with those colors. The chromaticity diagram allowed coordinate plotting of x and y color values to determine color (hue) and saturation (vividness).

The later development of the CIE L*a*b* color space allowed color to be expressed in a three-dimensional space (Figure 10). Because of the optic response of the human eye to blue, green, and red, calculations converted these responses to L*, a*, and b* values. When combined, these establish a three-dimensional color space. For the color space, a* values are represented on the x-axis, b* values on the y-axis, and L* values on the z-axis (Figure 10). In the center of the color space is neutral gray. Along the a* axis, a positive a* represents red, and a negative a* represents green (scale from +60 for red to −60 for green). Along the y-axis, a positive b* represents yellow, and a negative b* represents blue (scale from +60 for yellow to −60 for blue). The third dimension, L*, is represented numerically in which 100 is white and 0 is black (Figure 10). For this color space, a* and b* values can be plotted to establish the color or hue of a meat sample (Figure 11). Using the L* value, lightness or darkness of the sample can be determined. Therefore, using trigonometric functions, the incident angle that a sample deviates from the x-axis can be calculated to determine the hue angle of the sample, and the distance of the sample from the origin of the XYZ lines can be calculated to determine the saturation or vividness of the sample. Hue angle is calculated as h = arctangent (b*/a*). For example, with a CIE b* value of 14.12 and a CIE a* value of 47.63, the hue angle would be 16.51. Therefore, the plot of the a* and b* points into the hue angle formula will range from 0° to 360° to establish the color of the sample. Likewise, because colors become more vivid around the periphery of the color space, the farther the a* and b* plot points are from the origin, the more vivid the color. Chroma (saturation index) can be calculated from the a* and b* values as (a2 + b2)0.5. For example, with an a* value of 47.63 and a b* value of 14.12, the chroma (saturation index) would be 49.68. With these data, color differences can be calculated and compared objectively.

The physics of light and instrumental color measurements

Instrument packages come in 2 major classes capable of measuring color, the colorimeter and the spectrophotometer. Both use their own light sources and certain illumination conditions (e.g., Illuminants A, C, or D). Various light sources can be used (e.g., tungsten and deuterium). The part of the spectrum and the cost of the light bulb, among other things, influence the decision to use one light source over another.

Instruments differ in the way that they measure reflected light. The tristimulus method uses a light source that illuminates the sample and is then reflected through red, green, and blue filters onto photodetectors (Figure 12). The microprocessor can convert the reflected values to XYZ or CIE L*a*b* values. The spectrophotometer illuminates the sample, and the reflected waves are either scanned (via a monochromator) or read simultaneously by a photo diode array (Figure 13). These values are sent to a microprocessor and can be presented as the reflected spectra and converted to XYZ values as shown in Figure 12 or CIE L*a*b* values.

Some reflectance spectrophotometers are designed to scan wavelengths (colors) reflected from the surface using a diffraction grating, whereas others detect ranges of reflected light via photo diode arrays (a type of photo-detector capable of converting light into either current or voltage, depending upon the mode of operation). A diffraction grating is basically a solid plate with many parallel, closely spaced slits or a plate with many parallel reflecting grooves. Interestingly, a meat surface can also act as a diffraction grating itself. Iridescence seen on intact meat is related to the highly organized structure of the myofibrils within the fibers, so when the surface is cut, it can create a structure resembling reflecting grooves. In that case, the incident light is diffracted (as it would be using a prism) into a variety of hues. However, a spectrophotometer grating can separate the different colors of light much more than a prism with its dispersion effect. Even a single wavelength of light can be diffracted further. Photo diode arrays are designed to simultaneously measure a range of wavelengths. Some photo diode arrays may have a resolution of only 2 to 10 nm; therefore, with a very sharp reflectance peak or valley of interest, a scanning reflectance spectrophotometer may be a better choice. As photo diode arrays are improved, this advantage may be lost. Such high resolution is more pertinent to pigment analysis than tristimulus measurements. Also keep in mind that the scanning reflectance spectrophotometers collect the reflectance over the intended visible wavelength range much slower than diode arrays.

In addition, remember that meat contains multiple hues. For instance, fresh red meat appears red. Although the red hue dominates the spectral reflectance, other hues are also present. A spectral reflection profile is useful to determine the presence of other hues and their intensity. Furthermore, for pigment form, spectral reflectance can estimate pigment form quantities. Both colorimeters and spectrophotometers are useful to track color changes in meat over time because they are non-destructive tests. Important also is that instruments used to measure color vary widely in design features which impact the accuracy and precision of color measurements.

Display Guidelines for Meat Color Research

Purpose of display studies

Assessing meat appearance is a critical step in projecting the retail acceptance of meat products. Beyond meat’s intrinsic properties, many extrinsic factors can affect meat color, and research involving either type of variable often merits a simulated retail display study. The researcher must control all non-experimental factors to accurately discern actual differences due to treatment. The 6 parameters that should be considered, evaluated, and reported for any meat-display study are packaging, handling and storage, lighting parameters, display temperature, display duration, and display case configuration. Color evaluation during display studies typically involves at least one of 2 measurement methods: visual (panelists) and instrumental (colorimeter or spectrophotometer). Display studies may only include a single type of color assessment. If display focuses predominately on instrumental color measurements, it is very highly recommended that some “unofficial” visual descriptions of product color be taken at the start and termination of display so that authors can describe the general state of discoloration.

Packaging materials affect meat appearance

Package functionality

The functionality of any packaging system depends on the inherent, fundamental chemical and physical properties of the meat and their interactions with the various aspects of the packaging system. Hence, the materials and methods should contain antemortem details of the animal’s background, such as genetics, breed, sex, age, and production and nutritional history. In addition, pertinent details, such as the basis for treatment assignment to meat samples and replications, are needed as well as a complete history of postmortem events, such as stunning method, slaughter, electrical stimulation, chilling, carcass interventions, postmortem age, storage conditions of cuts, anatomical location of muscles and cuts removed, and geometric orientation of the muscle fibers.

Packaging materials

The type of film, bags, and trays/lids (e.g., rigid plastic or Styrofoam™) should be described using the manufacturer’s name, product number, chemical composition, thickness, bag size, oxygen and water vapor transmission rates, and—if appropriate—the color and position of the label. Packaging materials used in the study should also be used for training of visual panelists, for standardization of instrumental color measuring instruments, and for the development of myoglobin redox standards that can be used for quantification of myoglobin redoxforms.

Other considerations

The use of soaker pads, oxygen scavengers, or other atypical components should be detailed. Specifications (brand, model, composition, etc.) of additional components should be reported.

Atmosphere

The package atmospheric environment (gases or vacuum) must be considered. Often meat is overwrapped with film that is highly permeable to oxygen, but other formats are available, each with unique film/tray requirements. These should be carefully selected and clearly reported. In modified atmosphere packages, gas concentrations (molar or percentage concentration) should be monitored throughout display because minor variations can significantly affect meat color and color stability. To measure headspace concentrations, a headspace gas analyzer should be used, and the post-packaging time should be recorded.

Vacuum levels

If evaluating vacuum-packaged product, researchers should verify the vacuum level in the packages with a Kennedy Gauge (see Appendix E for information regarding this gauge) or an equivalent device to determine actual in-package vacuum levels. Vacuum levels from gauges near the vacuum pump often overestimate the in-package vacuum level. Researchers should be aware of the oxygen concentrations remaining in head spaces or in vacuum packages depending on the level of vacuum achieved. Even with high levels of vacuum pulled, significant oxygen may remain in the environment and impact MMb formation (see “Partial Pressure” in Appendix E).

Package failure

On occasion, a package may fail (package atmosphere becomes compromised or exposed) during a study. Failure may be the result of product mishandling, lost vacuum, poor seal integrity, or leakage during gas sampling. Be careful not to puncture packages with needles during gas measurements and check the stick-on septa for seal integrity. When visible package failure occurs or when there is an inability to maintain the desired atmosphere composition, that sample should be terminated from the study immediately and all data associated with it removed from data analysis. Because it is impossible to know when such failures occur or what effect the failure may have had on previous observations, an uncontrolled variable is introduced to the study, often invalidating conclusions.

Sample preparation

When preparing meat cuts or products for packaging, take care to standardize the time and conditions of exposure to atmospheric conditions before packaging. After the packaging process is complete, samples should be stored for sufficient time to allow equilibration with their atmosphere to occur (unless changes in the equilibration process are the subject of evaluation). For optimal and rapid blooming in oxygen-containing atmospheres, meat should be held at cold refrigeration temperatures, 0°C to 2°C, for at least 30 min. For adequate deoxygenation or pigment reduction in non- or low-oxygen atmospheres, samples may need to be held for longer periods at slightly warmer (4°C to 7°C; avoid abusive temperatures) temperatures to facilitate enzymatic scavenging of oxygen by the muscle and subsequent MMb reduction.

Microbial considerations

Care must be taken during sample preparation to reduce microbial contamination of product. Researchers should always start sample preparation with clean cutting surfaces and preparation tools. If knives are used, they must be regularly cleaned throughout preparation and rinsed thoroughly before reusing. The researcher and assistants should use clean gloves and change them frequently, taking care to avoid touching the product more than necessary and to avoid touching surfaces that will be evaluated for color and color stability.

Labeling

Each package should be labeled with a random 3- or 4-digit numeric identifier to facilitate panelists’ evaluations and to keep treatments unidentifiable, thus eliminating panelist and researcher bias.

Product handling and storage should mimic real-world parameters

Sample handling and processing should mimic industry practice as much as possible. Aging times should reflect those typical of the product being studied. Current commercial meat production and processing systems are changing to centrally packaged and distributed case-ready products. These products are seldom packaged and placed immediately into display. The complete handling system, especially postmortem age of the product and the time and temperature of storage (dark or lighted) should be described and reported.

Lighting types and intensity affect meat appearance

Light type and intensity will affect how product appears and its discoloration pattern. For most display studies, samples will be continuously subjected to a light source for 24 hours per day for the study’s duration. In addition, these studies should occur in a room where non-display lighting is not a factor and outside light sources are eliminated. However, if the display mimics retail store conditions, room lighting similar to lighting in retail stores would be appropriate. In this instance, case lighting and room lighting should be clearly detailed and reported. In the case of dual lighting situations, visual evaluations should be standardized for all samples and all panelists. Fluorescent, halogen, high-intensity discharge, incandescent, and light-emitting diode (LED) lights are all possible light sources for store and display lighting.

Even though meat may be viewed by consumers and researchers in a variety of different environments, meat research display studies should use either LED or fluorescent lighting. In most countries, fluorescent lighting is being converted to LED lighting because of less heat generation and more operating efficiencies. Because there is a wide availability of fluorescent and LED lighting, meat researchers must know that all fluorescent bulbs and LED lighting are not identical or interchangeable. Each type has its own individual properties, which affect meat color and color stability (Figures 14–15). Correctly selecting light sources for meat research, and reporting light source characteristic data, is critical.

This image depicts the various colors of light produced by different fluorescent bulbs lighting a coffin meat-display case. Note the 5 different colors, all indicating the need to remember that all fluorescent bulbs do not have the same color temperature and other properties. Courtesy of C. R. Raines, The Pennsylvania State University, and M. C. Hunt, Kansas State University.

This picture depicts the exact same unpackaged cuts of beef, pork, chicken, and hard salami under various fluorescent lighting types with different color temperatures and color rendering indices (see Meat Pictorial Guides E, Meat Lighting Facts of Appendix B). Courtesy of C. R. Raines, The Pennsylvania State University, and M. C. Hunt, Kansas State University.

Ideal meat-display lighting

Investigators should use only one bulb type per research study, unless lighting type is being studied. Lights in display studies should have a color temperature of 2,800 to 3,500 K and a color rendering index of 80 to 90. Lighting intensity should be between 1,612.5 and 2,152 lux (150 to 200 foot-candles; 1 foot-candle = 10.76 lux) as measured by a light meter at the meat level. Light intensity should be measured at multiple locations within the display case, including the sides. Front and back areas catch reflections, which can influence color stability. Lights should be adjusted above the displayed meat to produce a meat-level light intensity within this range. Dimmers and timers can be useful for simulating light intensities and exposure times at retail display.

Lighting with attributes to avoid

Cool white fluorescent bulbs are too blue and green (Section E, “Meat Lighting Facts,” in Appendix B). Similarly, color temperatures of 4,000 to 6,500 K are too blue and will not adequately represent meat color. High-intensity discharge bulbs may make meat products appear yellow. Lamps with greater output of UV light and short-wavelength visible light (blue, violet, and green) can accelerate discoloration of some fresh and/or cured meat products. However, UV light was about 2% of the total light and was less damaging than the short-wavelength visible light (Böhner and Rieblinger, 2016). Incandescent bulbs have an acceptable color temperature but may provide uneven illumination and excessive heating of the product, thereby accelerating discoloration.

Display temperature affects color life

Display temperature significantly influences meat color stability. Typically, the reported display temperature for meat color studies has been < 4.5°C. However, in many countries, retail case temperatures run higher under normal operation. In addition, case temperature will fluctuate and may include case defrost cycles sometimes exceeding, albeit temporarily, 10°C. If the display is in a cooler without a defrost cycle, this should be stated clearly because that is not a standard procedure in many retail stores. Regardless, continuous temperature monitoring is necessary to ensure the target temperature is achieved and maintained.

When setting up experimental procedures, researchers should select a display temperature appropriate to the goals of the research, which could be either ideal or abusive. Temperature control is essential if detecting true treatment differences in color or color stability is the goal. The recommended average display case temperature is 0°C to 2°C for non-abusive display temperature research. Investigators should distribute temperature loggers in various locations (front to back, side to side) of the case to continuously monitor air temperatures at the meat level. If multiple cases are involved, standardize the cases for temperature and monitor temperature profiles at identical locations within the cases prior to display.

When insufficient product is available to fill the retail case, investigators should consider filling the cases with packages of salt water (just enough salt to keep the water from freezing) to simulate a full case of meat. An appropriate number of defrost cycles for the display temperatures should be selected. Investigators should fully report the frequency, duration, and extent of the defrost cycles. Color evaluations (visual or instrumental) should not be scheduled during defrost cycles because some packages may “sweat” or form excess condensate inside the package during defrost. Packages displayed at a slight angle on the shelving allow condensate to flow to the edge of the package, without dripping on the product, thus preventing artificial discoloration.

Researchers must manage their samples carefully during display studies. Cases and product should be checked at least twice a day, if not more, to ensure temperatures are maintained within the specified range. During the display period, package location must be rotated within the case by randomly repositioning packages throughout the case once or twice daily. This will help reduce variability due to temperature and/or lighting intensity differences within the display case. In single-level (coffin) display cases, packages should be rotated daily to minimize within-case location effects from front to back and side to side within the case(s) during the display. Product rotation from one shelf to another shelf in multi-tiered cases is not recommended because lighting and temperature will vary across shelves. Thus, product rotation within a shelf is recommended using some scheme for side-to-side, front-to-back rotation. A study in which case temperatures are too high or too low results in erroneous data, lost research product, and unrecoverable time. Display studies are never a maintenance-free endeavor. If there are not enough test packages, other dummy packages, such as small freezer bags, should be used to mimic a full case of product.

Meat color evaluated against time to determine meat color stability

A primary objective of display studies is to evaluate color deterioration (or maintenance) over a given time period. Display studies can last a few hours to several days, weeks, or even months. Investigators need to determine an expected “end point” either before the trial begins or as it proceeds based on the color stability of the product(s) being evaluated. When scheduling a study, investigators should include extra days should product “last” longer than anticipated. Conversely, differences in color stability may be apparent short of the originally planned timeframe. The probability of either scenario can be limited by conducting a short, pre-trial study using factors of the main project. Panelists should be instructed to not handle packages or move them during display so differences in viewing angle or distance among panelists are not introduced.

Configuring a meat-display case

Meat-display studies can be conducted in single-level or multi-level display cases. The requirements discussed previously remain the same. Single-level cases make it easier to manage light intensity, keep visual distance from the product consistent during evaluation, and avoid tier-to-tier temperature variation. However, if multi-level cases are used, temperatures and light intensity at the meat level on each tier within the cases should be monitored and reported.

Occasionally, display cases of either configuration type may not be available for color studies. If this occurs, large, refrigerated rooms (e.g., walk in coolers) may be used. However, researchers must construct lighting structures and display surfaces that maintain consistency for light, temperature, and product. Light sources within the cooler other than the display lighting must be eliminated. People coming in and out of the cooler must be minimized to reduce temperature fluctuations and outside light. Under such conditions, researcher vigilance is even more important for monitoring the meat-display conditions.

Display factors to report

Numerous items have been presented, and nearly all of them should be reported in articles containing data for a simulated meat color stability display study.

Visual Appraisal Principles for Meat Color Measurement

Visual appraisals of color are the “fundamental standard” of color measurements because they closely relate to consumer evaluations and set the benchmark for instrumental measurement comparisons. Like all sensory evaluations using human panelists, visual color panels are not easy to conduct because human evaluation may not be replicable from day to day and is influenced by personal preference, lighting, visual deficiencies of the eye, and environmental appearance factors other than color. Moreover, meat color cannot be stored, maintained, or reliably reproduced over time. Yet, through proper panel management, sample presentation, and data collection procedures, visual appraisals of color can provide accurate and repeatable objective data. These guidelines will provide a brief overview of key concepts that must be understood and practiced when preparing to conduct sensory studies, including visual color panels or studies using only instrumental color measurements.

Conducting research using human panelists

Before sensory work is initiated, most educational, research, and governmental entities are obligated to contact their institutional review board (or similar group) to obtain approval of the details and protocol as mandated by federal laws and regulations for the oversight of all activities involving research with human subjects. Obtaining proper informed consent of panelists is part of this approval process. There are very few exceptions to the requirement for obtaining this approval. Some scientific journals also require evidence of the proper use and approval of human subjects in research. Do not wait until the last minute for obtaining these approvals because there may be several levels of approval needed.

Key concepts for conducting color research using human panelists are presented in Table 1. These guidelines provide only a brief overview of sensory techniques as they apply to evaluating meat color. More detail on sensory methods are in the American Meat Science Association Research Guidelines for Cookery (AMSA, 2016), Sensory Evaluation, and Instrumental Tenderness Measurements of Fresh Meat, in ASTM (ASTM Committee E-18, 1968a, 1968b, 1978, 1979, 1981) and IFT publications (IFT Sensory Evaluation Division, 1995), as well as Meilgaard et al. (1991) and Miller (1994). These documents focus primarily on sensory methods for flavor and tenderness evaluation but provide extensive guidance on training and conducting sensory panels, much of which applies to visual panels as well. Thus, these documents should be thoroughly reviewed before initiating visual color evaluation studies. Additionally, these documents highlight what information should be provided when publishing sensory research. A list of such information is presented in Table 2.

Key steps to conducting trained descriptive visual color research panels

| Item | Description |

|---|---|

| Use human panelists | Gain the appropriate approval(s) for use of human subjects in research |

| Select panel type and appropriate scales | The panel type and scale should appropriately address the objectives of the experiment. |

| Identify panelists | Panelists should have normal color vision and acuity, which should be assessed with the Farnsworth-Munsell Hue test. Select a panel leader. |

| Conduct preliminary trial | A small preliminary trial should be conducted on samples treated in accordance with the experimental protocol. |

| Scale refinement | During the preliminary trial, scoring scales can be adjusted to reflect changes observed in samples during the preliminary trial. |

| Panel orientation/training | During the preliminary trial, panelists should be oriented to the scales and trained to score samples equally. |

| Conduct the experiment | Panel viewing conditions should be standardized. |

| Monitor panel performance | Panelists’ scores should be monitored in reference to panel leader scores. Preliminary analyses including panelist × treatment interactions may indicate shortcomings in panel performance. Panelists identified as not performing adequately should be excluded and/or retrained. |

| Statistical analysis | Average panelist scores and apply appropriate statistical models. |

Information that should be reported in scientific reports with trained descriptive visual color panel data

| Item | Description |

|---|---|

| Type | Consumer or trained |

| Panel selection criteria | Normal vision, acuity, prior experience, etc. |

| Number of panelists | Minimum number of panelists each day (if different from total) |

| Training | Number of sessions, standards used, pictorial standards (if used), etc. |

| Display and viewing conditionsa | Lighting, packaging, and other pertinent factors; see Display guidelines |

| Session descriptions | Days of display evaluated, number of samples per session, time of day if varied, etc. |

| Scales | Establish anchors and descriptors in allowed increments (if applicable) |

| Statistical methods | Experimental design and statistical analysis |

This information should be reported if different from the display/storage conditions.

Types of visual panels

Color panels can be broadly classified as trained visual color panels or consumer panels. Trained, descriptive visual color panels are most commonly used in meat color research and can be regarded as objective instruments. Trained descriptive panelists undergo rigorous screening and training to obtain quantitative ratings of samples on anchored scales. These panelists should not be asked to rate personal preferences or acceptability of the samples they evaluate. Consumer panelists, on the other hand, are useful for providing information using hedonic scales of their preferences and the acceptability of the product’s attributes. The particular research question determines which type of panel can provide data that address that research question. To fully address all pertinent questions, using both types of panels may be appropriate.

Selecting panelists

Consumer panelists

Consumer panelists are generally recruited from predefined demographic groups based on the population of interest. For example, a consumer panel made up of 18- to 21-year-old college students may not provide responses representative of older, more affluent professionals being targeted by branded programs. It may be advantageous to target panelists that meet certain criteria, such as being the primary grocery shopper or food preparer in their family. Consumer panelists generally are given only basic information required by informed consent regulations and receive no training other than instructions in completing the ballot or questionnaire. Consumer panels may be conducted by allowing panelists to rate products on their own in a home environment, which provides consumer perceptions in the environment in which a product is to be used. However, this approach is prone to data recording errors and incomplete results. Alternatively, panelists may be brought to a central location and presented products under controlled conditions with researchers available to help record data. Such “capture panels” allow more correct and complete data, but resulting consumer perceptions fall outside “typical use” conditions. Regardless of location, a sufficient number of panelists must be recruited to avoid bias. The number required will depend on the products and criteria to be evaluated, but a rule of thumb is that a consumer study should involve at least 100 consumers.

Trained descriptive visual color panels

ASTM-434 (1968b) suggests a minimum of 5 panelists, because using fewer than 5 depends too much upon any one individual’s response. Typically, a minimum of 8 panelists are used to evaluate each sample, though otherwise unsuitable panelists should not be used simply to meet an arbitrary number of panelists. Because color panels are generally conducted over many days, a larger panel may be beneficial so panelists’ other obligations do not prevent the required number of observations being obtained.

Training panelists

At a minimum, trained descriptive panelists should be recruited and initially screened based on availability, interest, and normal acuity (such as not being color blind), and they should be able to discriminate color differences using a Farnsworth-Munsell 100-Hue test (see Appendix E for more information). The Farnsworth-Munsell 100-Hue test can be taken online at http://www.xrite.com/custom_page.aspx?PageID=77andLang=en. Successful panelists should have a score of 50 or less if possible (prospective panelists with scores of more than 100 should not be used). Kinnear and Sahraie (2002) reported that panelists between ages 14 and 59 y scored better on the 100-Hue test than those outside this age range. Further training should confirm panelists’ ability to provide accurate and repeatable data using an anchored scale. During this time, the lead investigator or other highly experienced person should serve as the panel leader, providing guidance to panelists on the scale and ensuring that panelists score samples equally. A pre-trial orientation for panelists should include discussions of time requirements; projected dates of evaluation; orientation to packaging, display conditions, and data sheets; and a discussion of color descriptors. A preliminary trial also provides an excellent opportunity for panel orientation and training, as well as any necessary adjustment to the scales being used. Panelists generally should not be aware of the treatments being studied unless that information would help them adequately assess samples. In any case, panelists should not be aware of the treatments to which individual samples belong.

Scoring scales

The relevance of the results of color research conducted with trained descriptive visual panelists relies heavily on the suitability of the color scale. The scoring scale must be properly constructed to obtain data that characterize differences (or lack thereof) between experimental treatments. Thus, the color scale itself must address the correct research questions to be useful. An ideal scale for characterizing discoloration of fresh beef steaks will be of little value in characterizing the fading of cured, frozen pork chops. Furthermore, some scales ask the panelists to provide an “average” color value for an entire sample, whereas others specify the “worst-point” color. Both approaches are informative but yield different results, and investigators must decide which approach will give results most relevant to a particular experiment and the question that experiment attempts to answer.

Panelists need to know whether they will be evaluating initial color and/or color change during display. These require different scoring scales. Often the initial color is characterized at the beginning of display, whereas the color change is evaluated using discoloration scales at the beginning of display and various storage/display times. If percentage discoloration (due to any “deteriorative color” or to MMb, specifically) is evaluated, be sure that the percentage breaks in the scale are realistic and reflective of consumer discrimination. Research generally shows that consumers start to detect and discriminate against surface MMb levels 15% to 30% of the total area, but the area covered by the discoloration needs to be carefully categorized by percentages (for examples of discoloration scales, see Appendix A).

When possible, pictorial aids should accompany the scoring scales (see Appendix B for example pictorial aids). Photographs taken during pre-trials before the actual experimental study begins are particularly useful as a reference for subsequent scoring scale refinement and during panelist training and practice sessions. Pictorial color standards should be stored in the dark because most are subject to light-induced color changes. Often, high-quality photographs of meat that are very representative of OMb, DMb, MMb, good cured color, and typical faded cured color are extremely useful. These scales and pictures are provided because they have been used successfully in research trials and can serve as a template for designing scales in future research. However, investigators should note that conditions unique to each experiment (such as, e.g., display temperature, postmortem age, frequency and duration of defrost cycles, lighting intensity) as well as experimental treatments will alter changes observed during any given display study. Therefore, conducting preliminary trials is best, with meat treated as prescribed by the experimental protocol. In this way, the selected scale can be compared with observed changes in color and adjusted as necessary. Furthermore, researchers should note that hedonic scales appropriate for consumer panels differ in aim and scope from the quantitative scales appropriate for trained laboratory panels.

Sample presentation

Regardless of the type of panel, results depend greatly on sample presentation and the conditions under which samples are presented. As is the case with any analytical technique, color evaluation must overcome the fundamental problems of obtaining a representative sample. Sample preparation for color measurement requires standardized procedures that are both repeatable (by the same person in the same laboratory) and reproducible (by different people in different laboratories at different times). All samples must be handled in the same manner to prevent artifacts. This is particularly important when live animal treatments are evaluated for their effects on meat color. Factors for which standardization is especially important include (unless the factor is an experimental variable) animal nutritional regimen, carcass chill rate, muscle, sample location within a muscle, muscle fiber orientation, muscle pH, time and temperature of postmortem storage, muscle exposure time to oxygen, marbling content and distribution, surface wetness and gloss, myoglobin concentration, packaging, and display conditions (see the previous discussion of display conditions for more details).

Color viewing conditions

Presentation conditions are critical to sensory evaluation. The environment should be free of distractions. Panelist fatigue can affect the accuracy and repeatability of evaluations, so the number of samples must be reasonably limited. The number of samples that panelists can score in a single session will be greatly influenced by the number and complexity of attributes to be evaluated. Because perceived color depends on light source and viewing angle (see earlier review of the physics affecting meat color), these factors must be standardized. Meat color evaluation panels are often conducted with products in simulated retail display. Thus, the display environment must be conducive to panel data collection. For studies evaluating color stability during display, all panelists should be asked to score samples within a small time window (e.g., between 0900 and 1100) on each evaluation day. Sample evaluation should be timed to avoid defrost cycles, because condensation may form in the packages and hinder proper evaluation as described earlier.

Sample identification

Sample identification numbers should be a randomly assigned, 3-digit number that does not indicate treatment group or subconsciously introduce other bias. For example, a panelist may subconsciously give higher scores to a sample identified as number 1 than to a sample identified as number 2. Numbering systems should blind panelists to treatment assignments. This is particularly important in the case in which investigators familiar with the treatments must be pressed into service as panelists.

Monitoring panelist performance