Introduction

Industrial robots have played a major role in modern automated manufacturing operations for all sorts of applications, such as welding, painting, material handling, packaging, labeling, assembling, product inspection and testing, etc. Incorporating industrial robots into current robotics curricula has become a key component for engineering technology programs (Sergeyev & Alaraje, 2010). Recently, Toyota Motor Engineering & Manufacturing North America donated a Kawasaki ZB150S industrial robot to the engineering technology programs at Northern Kentucky University for student robotics experiments. When students work in the robotics laboratory, lab safety is the most important concern as accidents can easily occur. It is critical to pay attention to the proper care and usage of robotics that students use in the lab. It should be pointed out that many robot accidents do not occur under normal operating conditions but instead during programming, program touch-up or refinement, maintenance, repair, testing, setup, or adjustment. During many of these operations, the operator, programmer, or maintenance worker may temporarily be within the robot’s working envelope, where unintended operations could result in injuries (OSHA, 2020).

To protect students from injuries caused by the unexpected movement of the robot, the whole robot system shown in Figure 1 was installed in a safeguard cage that was built out of extruded aluminum and paneled with recycled Plexiglas and steel wire mesh. However, the safeguard cage could not always prevent unauthorized students from coming into the working area of the robot. Lab staff could not always monitor and record occurrences of unauthorized operating conditions in the robotics lab. Thus, the lab manager expressed an urgent need for a low-cost, simple to operate, and intelligent monitoring tool to improve lab safety. The monitoring tool was expected to contain a Global System for Mobile (GSM) module that can alert lab staff immediately when students enter the safety cage without permission. This would allow for a more meaningful interaction among students and lab manager with quantifiable and objective data regarding these situations as opposed to subjective reporting.

There are several prior lab/office or warehouse monitoring systems that used GSM technology. Gagliarducci et al. (2007) used the GSM module to remotely monitor and control complex stand-alone photovoltaic plants. Through the GSM cellular networks, the incorrect behaviors of photovoltaic plants can be immediately reported to the operators. In addition, users were able to modify the settings of the plant and measurement system in the office. A remote laboratory safety monitoring and alert system was built by Ramya et al. (2012). They incorporated the gas and fire detection sensors into the PIC16F877 microcontroller-based monitoring system. Once biohazards such as fire or gas leaks are detected by the monitoring system, the voice alarm and alert messages can be remotely transmitted to the lab manager through GSM communication. Thus, this system provided faster response time during an emergency in the laboratory. Zheng et al. (2016) designed a remote temperature and humidity monitoring system in the food storage warehouse. The environmental measurements could be sent to various monitoring devices via GSM communication.

In the literature, little attention has been paid to integrating laboratory safety and GSM communication into one control system. The overarching goal of this project was to design a GSM-based intelligent monitoring system to provide a safe robotics lab operating environment for students.

Materials and Methods

This research was part of the project titled “Installation of a Kawasaki ZB150 Industrial Robot.” The design team consisted of three faculty members and four student research assistants. For the GSM-based intelligent monitoring system development, the entire design process came into fruition through a sequence of product development phases: research phase (4 weeks), design phase (20 weeks), testing phase (2 weeks), modification phase (4 weeks), installation phase (2 weeks), and closeout phase (2 weeks). In the design and testing phases, we created a Conceptual Block Diagram (CBD) of the system first to show the basic functions and functional requirements. The next stage was to take the functional requirements and produce their respective performance specifications. These specifications were quantitative measurable values for each of the functional requirements (e.g., power, interface protocol, etc.). Then, we made a Functional Block Diagram (FBD) to depict all the parts chosen. The FBD contained pins, signals, and all interfaces required for each hardware unit to function properly. Next, we used Eagle CAD professional design software (Autodesk-Eagle, 2020) to draw the detailed system schematic and Printed Circuit Board (PCB) layout. The PCB board manufacturer (Seeed Fusion, 2020) fabricated the boards. Lastly, we tested each hardware unit and evaluated the software to make sure that the whole system could deliver the overarching functionality.

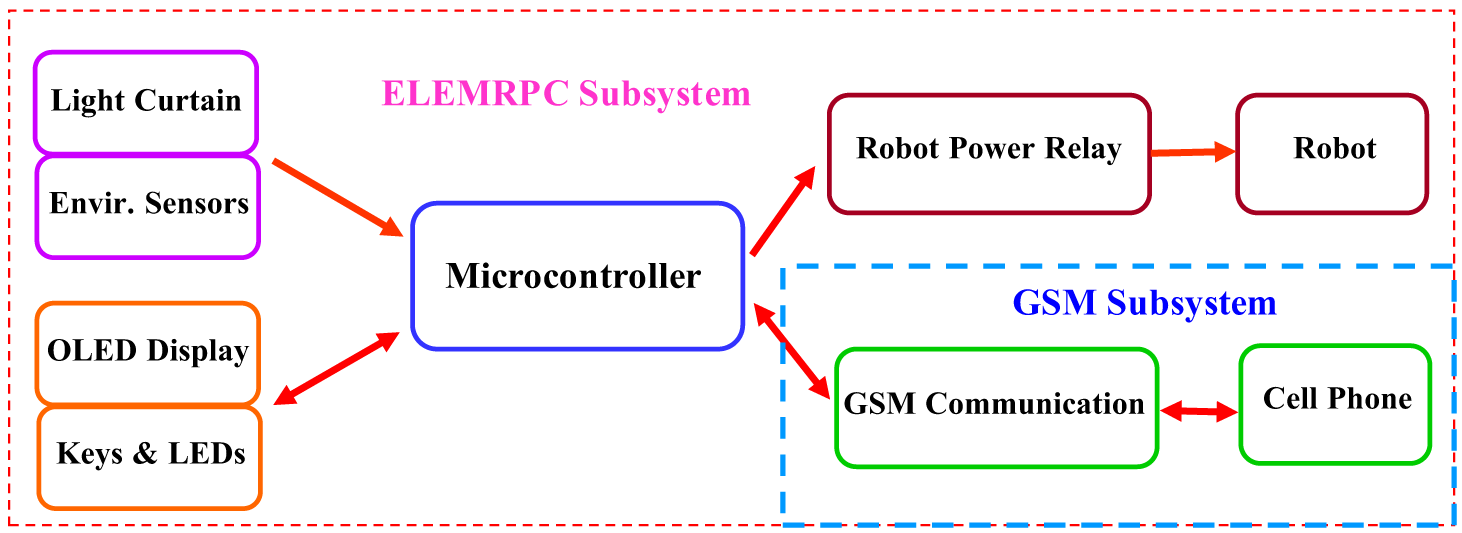

Figure 2 shows the CBD of the intelligent robotics laboratory safety monitoring system, which was divided into two subsystems. One subsystem was the Embedded Laboratory Environmental Monitoring and Robot Power Control (ELEMRPC) subsystem; this subsystem included a microcontroller, infrared presence sensors (light curtain), environmental sensors, an organic light-emitting diode (OLED) display, system status indicators, keys, and a robot power control unit. The other subsystem was the GSM communication subsystem; in this subsystem, robotics lab safety information and environmental parameters can be wirelessly transmitted to the lab manager via GSM communication.

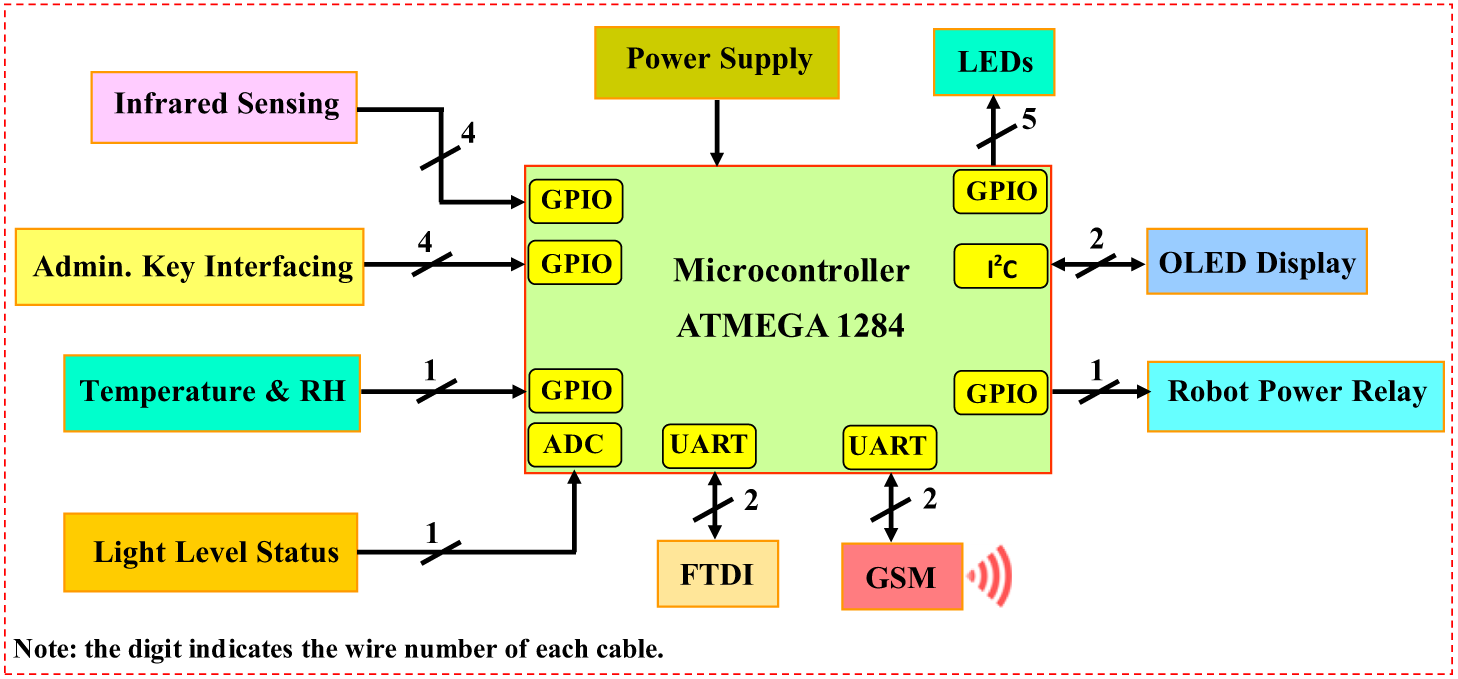

The overall FBD was made to support simultaneous design and development of both hardware and software. As can be seen in Figure 3, the core of the entire ELEMRPC subsystem was the Microchip ATmega1284 microcontroller. This microcontroller was used to (1) receive inputs from the multiple environmental sensors to measure indoor light level, temperature, and humidity parameters; (2) determine whether individuals were within the footprint of the robot safety cage based on the infrared presence-sensing signals; (3) control the power relay to arm/disarm the power supply of the robot; (4) allow the administrators to change system settings through the on-board keys; and (5) show parameters on the local OLED display. The GSM communication subsystem can wirelessly send text messages to designated cellular phones when preconfigured parameters are exceeded.

The FBD of the intelligent robotics laboratory safety monitoring system. ADC, Analog to Digital Converter; FBD, Functional Block Diagram; FTDI, Future Technology Devices International; GPIO, General Purpose Input/Output; GSM, Global System for Mobile; I2C, Inter-Integrated Circuit; OLED, Organic Light-Emitting Diode; RH, Relative Humidity; UART, Universal Asynchronous Receiver Transmitter.

The ELEMRPC subsystem

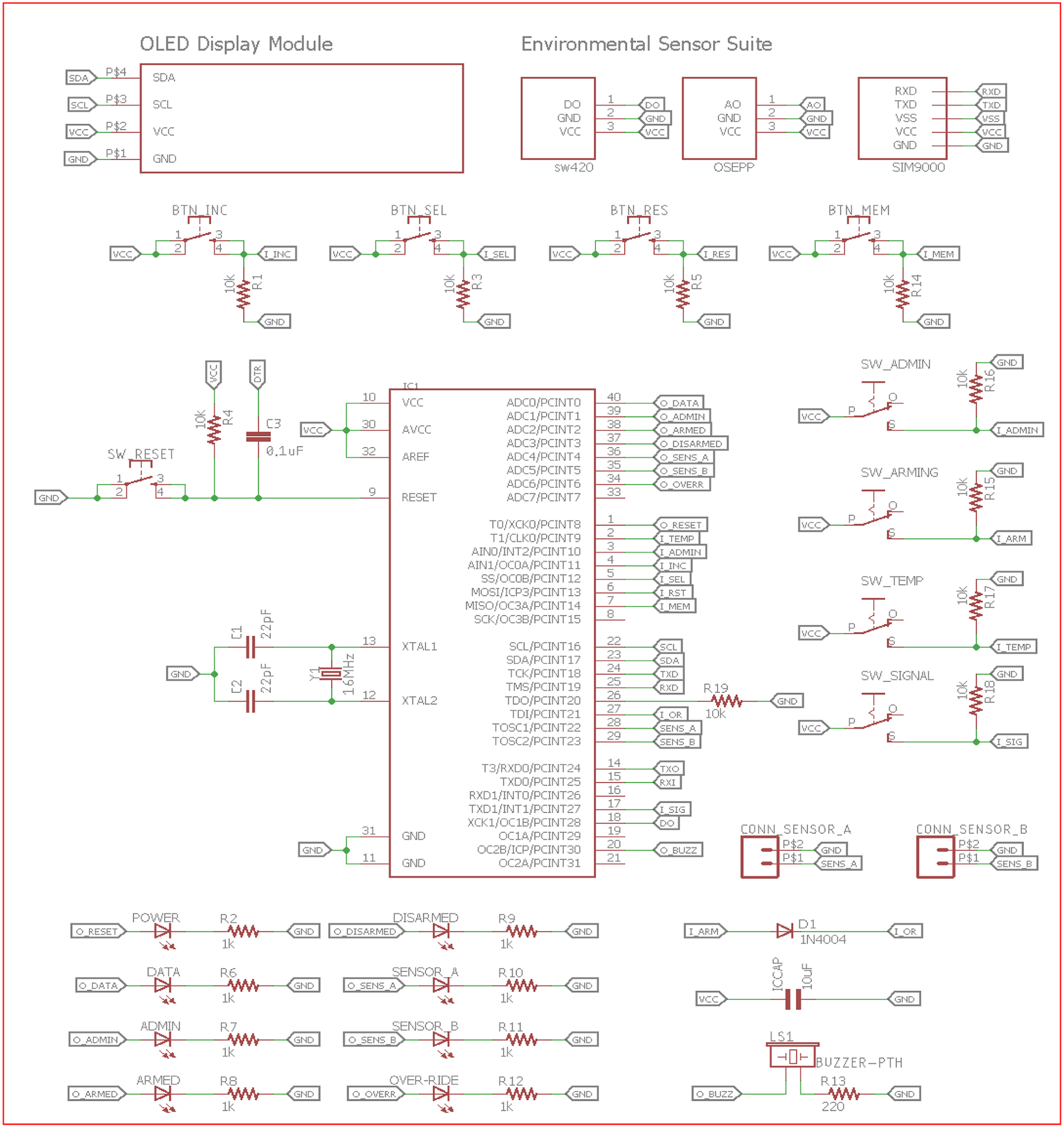

The ELEMRPC subsystem received the presence-sensing signals from the infrared sensors and controlled the power relay to disable power to the robot when unauthorized students were detected. In addition, the lab environmental parameters were monitored and recorded. Figure 4 exhibits the schematic of the ELEMRPC subsystem for environmental parameter monitoring, presence sensing, key interfacing, OLED display, and robot power control.

Microchip microcontroller. The Microchip (Atmel) ATmega1284 (Microchip, 2020) was chosen as a major system controller because it is a high-performance and low-power Complementary Metal Oxide Semiconductor (CMOS) microcontroller with a multitude of advanced features. It has 128-KB In-System Programming (ISP) flash memory with read-while-write capabilities, 4-KB Electrically Erasable Programmable Read-only Memory (EEPROM), 16-KB Static Random Access Memory (SRAM), 32 General Purpose Input/Output (GPIO) lines, three flexible timer/counters, an 8-channel 10-bit Analog/Digital (A/D) converter with optional differential input stage with programmable gain, and six software selectable power-saving modes, etc. The large EEPROM allows for storage of multiple phone numbers, text message templates and provisions for data and event logging. Furthermore, an additional strength of the ATmega1284 is the reduced instruction set (RISC) architecture. The RISC architecture utilizes a small and highly optimized set of instructions, rather than a more specialized set of instructions often found in other types of architectures (e.g., complex instruction set computers). With the RISC architecture, the ATmega1284 microcontroller can produce code more efficiently. By using the Visual Micro plugin for Microsoft Visual Studio 2017, the code can be written in C and loaded to the microcontroller via the use of a Future Technology Devices International (FTDI) equipped USB cable.

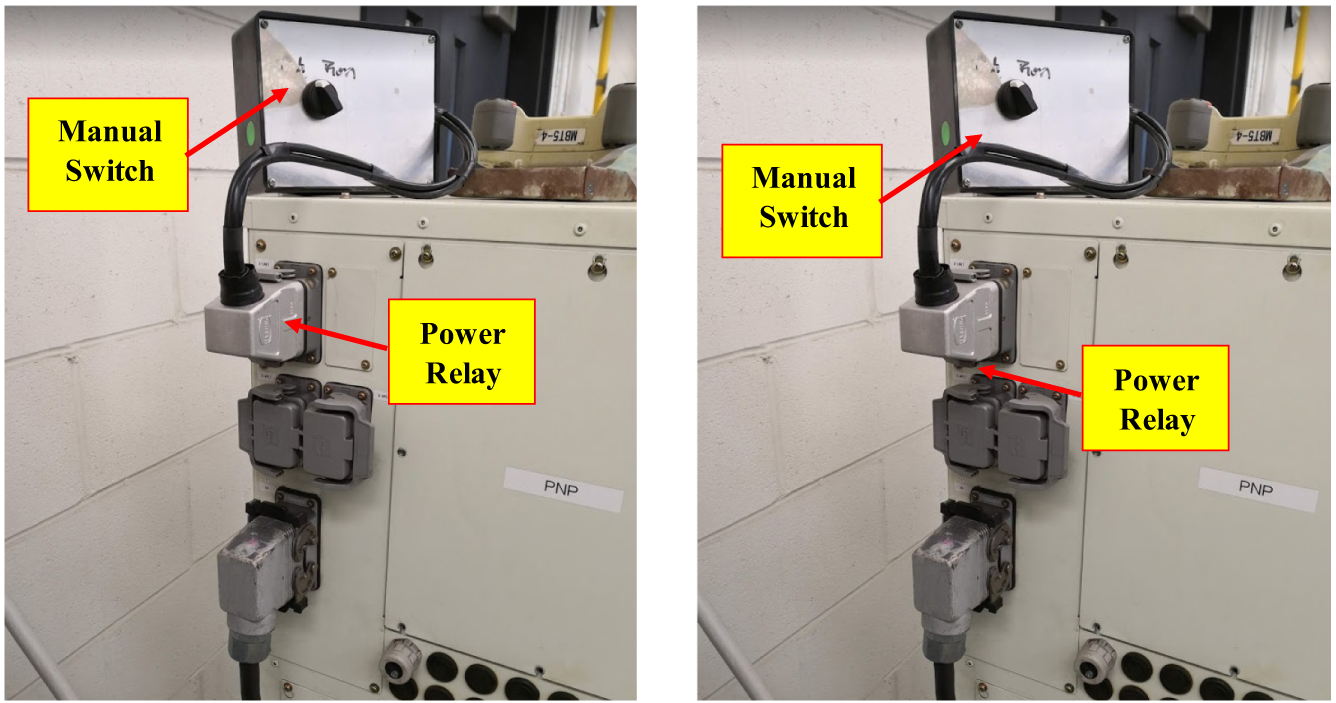

Presence sensing and robot power control. Four retroreflective cylinder amplifier photoelectric sensors (TAISS PNP E3F-R2P1, Suzhou Taihun Electronics Co., Ltd.) were utilized in this project because they have excellent immunity to ambient light and electric noise. These photoelectric sensors were easily installed at the safeguard cage entrance to form a light curtain. The light curtain can detect whether a person is present within the robot safety cage without the lab manager’s permission and then sends a detection signal to the ATmega1284 microcontroller. As soon as the microcontroller received the input signal, it immediately energized the power relay to shut off the power supply of the robot. The robot power on/off could be manually controlled by the switch (Figure 5).

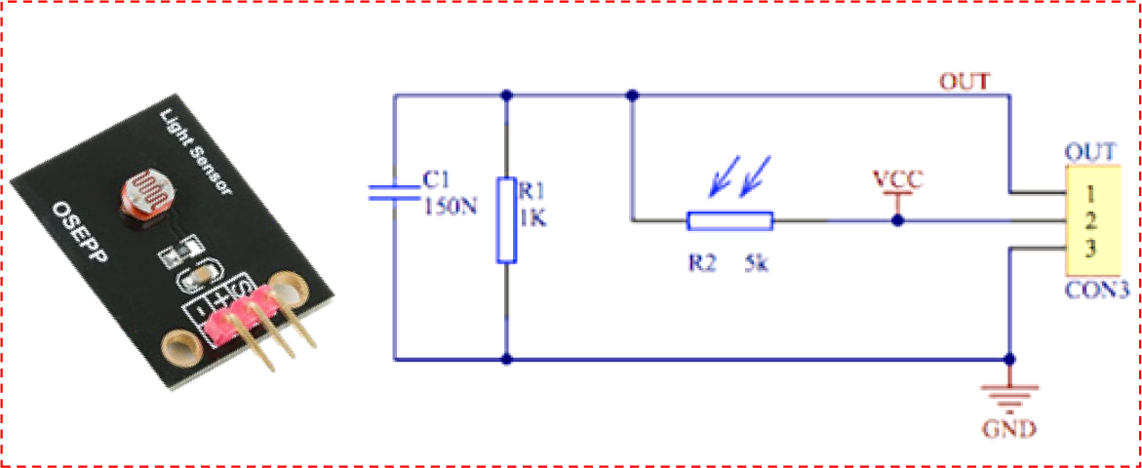

Laboratory environmental parameter monitoring. One of the environmental and security criteria tracked via the ELEMRPC subsystem was the light level status of the robotics laboratory (Figure 6). The light level was obtained via the use of a Cadmium Sulfide (CdS) photo-resistor (OSEPP, ShenZhen HaiWang Sensor Co., Ltd.), which generated an analog signal between 0 V and 5 V depending on the strength of the light that it was exposed to. The light sensor was configured for a binary input outputting “On” or “Off” based on the voltage output level.

The environmental digital sensor (DHT-11; Shenzhen Robotlinking Technology Co., Ltd.) was used to measure laboratory temperature and relative humidity. The DH-11 module (Figure 7) has solid state sensors with resistive-type humidity and Negative Temperature Coefficient (NTC) temperature measurement components. It is strictly calibrated in the lab. No additional sensor calibration is needed. Its on-board analog-to-digital converter can interpret the signal from the sensor and transmit it to the microcontroller, which then parses the data and stores it as a string in the text buffer. Each sample was compared to the text buffer and was only updated when a change in parameter was received. To avoid errors to temperature and humidity levels due to heat generated by the power supply, the DHT-11 module was mounted externally on top of the enclosure and connected to the main board via a three-line ribbon cable providing VCC (the power input), GND (ground), and signal paths.

The three environmental parameters can be viewed directly on the OLED display screen or queried via GSM by texting the command “ENV” to the intelligent robotics laboratory safety monitoring system—this triggers the command language parsing function and returns a text to the phone issuing the query that included the current temperature, relative humidity, and lighting level status.

Key interfacing and OLED display. In operation, the appropriate monitoring system state (“armed,” “disarmed,” “run,” “admin.”) was selected by the setting of the multi-position key switch. The system state was displayed on the OLED display screen and the appropriate status LED illuminated. The following is a list of I/O actions for each state:

- ➢

“Armed” state: When the key switch was in the “Armed” position or the “System Armed” text message had been sent from a designated cellular phone, the intelligent robotics laboratory safety monitoring system entered the armed state. The OLED displayed a rotation of “System Armed,” Temperature and Humidity, and a green-color LED was illuminated. A signal from the presence sensors generated a warning tone until the presence was removed, and a preconfigured GSM text message was transmitted to the designated cellular phones.

- ➢

“Disarmed” state: When the key switch was in the “Disarmed” position or the “System Disarmed” text message had been sent from a designated cellular phone, the intelligent robotics laboratory safety monitoring system entered the disarmed state. The OLED displayed a rotation of “System Disarmed,” Temperature and Humidity, and a red-color LED was illuminated.

- ➢

“Run” state: When the key switch was in the “Run” position, the system entered the “Run” state. The OLED displayed “System Run,” and a blue-color LED was illuminated along with a double beep. In this state, a signal sent from the presence sensors can switch the solid-state relay (SSR) off, disabling the robot.

- ➢

“Admin.” state: When the key switch was in the “Admin.” position, the system entered the “Admin.” state. The OLED displayed the primary phone number programmed into the monitoring system, and a yellow-color LED was illuminated along with a double beep tone. The SSR was “OFF,” and in this state, GSM inquiries and commands were disabled. While in the “Admin.” mode, the four momentary pushbuttons on the control panel became active and allowed the user to (a) change, add, or delete phone numbers stored in the system phone number data table so that data can be preserved in the event of a power failure or system reset and (b) change temperature display from Celsius to Fahrenheit.

The GSM communication subsystem

The unique feature of this intelligent laboratory safety monitoring system is that the alert text messages along with the environmental information can be wirelessly transmitted to designated cellular phones via GSM networks. The remote arm/disarm commands, system status updates, and inquiries of current laboratory environmental data can be also sent via GSM from authorized cellular phones to the intelligent monitoring system.

By utilizing the global second-generation cellular network (2G) data network and a quad band (850, 900, 1800, and 1900 MHz) transceiver, SIM900 GSM modules (SIM900, SainSmart Technology, Inc.) are easily implemented globally and tied to any cell provider. The SIM900 module comes with a Universal Asynchronous Receiver/Transmitter (UART) adapter that can be directly interfaced to any microcontroller through a UART peripheral—TX (Transmit) and RX (Receive) pins with 1200 to 115,200 bps baud rate. Because the SIM900 module leverages the global GSM network and quad band transmission, its hardware can be easily implemented anywhere within the 90% of the globe that is covered by 2G. Unlike devices that rely on local radio networks such as Bluetooth or Wi-Fi, there are none of the distance or network concerns for GSM communication.

After a valid SIM card was placed into the SIM socket of the SIM900 module and the connection with mobile network was successfully established, the microcontroller ATmega1284 was able to control the GSM module using AT (AT is the abbreviation of Attention) commands. This GSM module supported a set of AT commands that were defined in the GSM standards. For example, the “AT+ 0185999xxx” command was used to call the GSM module number 859-999-xxxx. The “AT+CMGS=1” command was used to select SMS message format as text. The “AT+CMGR=1\r” command was used to read the first SMS from the inbox.

The Intelligent Robotics Laboratory Safety Monitoring System Manufacturing and Integration

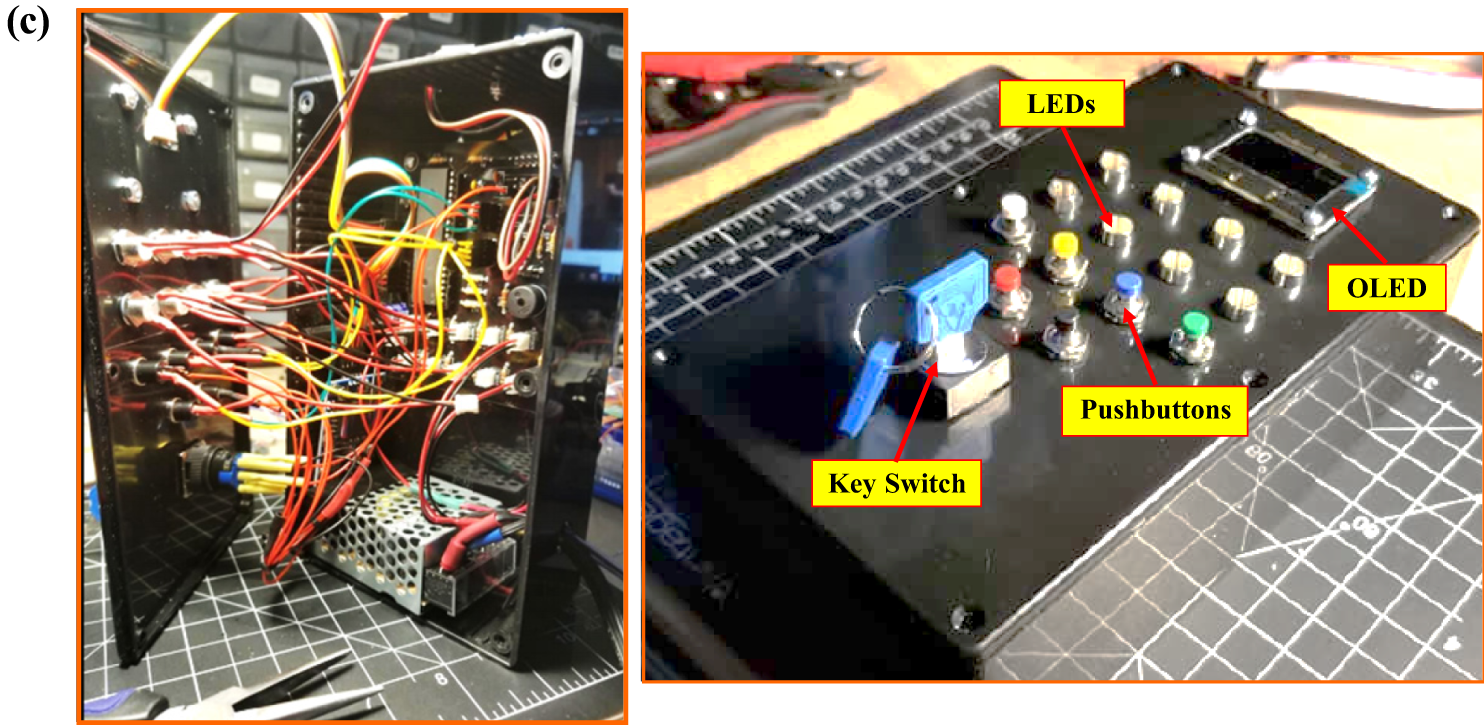

As shown in Figure 8 (Figure 8a, 8b, and 8c), the intelligent laboratory safety monitoring system was designed, manufactured, and assembled. A prototype “proof of concept” system (Figure 8a) was constructed on the solderless breadboard to ensure that design requirements were met. Each key hardware unit was verified, such as the microcontroller I/O interfacing circuits for keys and LED indicators, OLED display, environmental parameter measuring, and GSM module. The electrical measurements (e.g., power consumption, electrical interference, power supply stability) were also conducted to test whether they were within design parameters. In addition, this prototype system allowed for easy programming and code adjustments to the microcontroller because it was directly connected to a computer via an FTDI programming header. The software development work was to write, debug, and test C code that was required by the ATmega1284 microcontroller to perform the functions of GPIO, I2C (Inter-Integrated Circuit), and UART interfaces, and timer in the integrated development environment (Microsoft Visual Studio 2017).

Once correct functions were obtained, a custom PCB (Figure 8b) was designed and laid out using Autodesk Eagle software. The Gerber files were sent to the PCB manufacturer to fabricate final PCB boards. After the PCB boards were made, the electronic components were populated on the boards (Figure 8b).

Once the PCB board was assembled, it was placed into a standard locking non-metallic industrial enclosure (Figure 8c). This enclosure contained the system 120VAC to 5VDC 2-amp power supply, custom PCB boards, the SIM900 GSM module, an external antenna, a keyed system state switch, an OLED display, an audible tone generator, LED indicators, and four momentary pushbuttons. Connections were provided for data signals from various sources such as the lab indoor light, temperature, humidity, and the presence-sensing devices. Connections were also for the control signal to the SSR handling control power to the robot.

The Intelligent Robotics Laboratory Safety Monitoring System Testing Results

After the system level requirements and main system architecture were developed, we created a test matrix to account for all the tests needed to ensure proper functionality of the intelligent monitoring system. As shown in Table 1, the test matrix was put in place to confirm that all functional requirements were met by the final prototype. The functional requirements are listed on the X-axis, and related tests are listed on the Y-axis. The “X” that falls into both of these axes indicates where a test validated a requirement. The rows with more than one X designate a test that was able to verify multiple functional requirements. The testing results for each functional requirement are presented as follows.

The test matix of the intelligent laboratory safety monitoring system.

| Test Matrix | Phone Number Data Table Update | Cellular Communication (GSM) | Environmental Parameter Measurement | Safeguard Cage Presence Sensing | Robot Power Control |

|---|---|---|---|---|---|

| Power Supply Test | X | X | X | X | X |

| Multi-position Key Switch and Buttons Test | X | X | X | X | |

| Environmental Sensors Test | X | X | |||

| GSM Module Test | X | X | X | ||

| OLED Display Test | X | X | X | ||

| Retroreflective Photoelectric Sensor Test | X | ||||

| Robot Power Relay Test | X | X |

GSM, Global System for Mobile; OLED, organic light-emitting diode.

Multi-position key switch and buttons testing

The most challenging aspect of the intelligent system development was to update phone number table in the EEPROM memory only using four buttons: “INC” (Increment), “SEL” (Selection), “RST” (Reset), and “MEM” (Memory) buttons. Figure 9 depicts the phone number data input using those four buttons that were placed in the front panel of the enclosure.

When the key switch was placed in the “Admin.” position, the OLED displayed the current phone numbers stored in the memory, and the cursor started under the first digit. The “INC” button was pressed to increase the number from its current value, rolling back to “0” after “9.” Once the correct number was displayed, the “SEL” button needed to be pressed to accept that number and move the cursor to the next digit. Then, the “INC” button was pressed again to change the second number. This process was continued until all 10 digits had been updated. If an error was made, pressing the “RST” (Reset) button would return the cursor to the first digit position. After the number was entered correctly, the “MEM” button was pushed to write the phone number into the EEPROM, where it remained even if power was lost or the system was restarted. In the code, a phone number array was created to hold the 10 digits of a phone number. A cursor location array was also made to define the pixel location of the OLED cursor. This cursor location array matrix utilized the change in cursor position as a pointer to retrieve each array element. Those two arrays (phone number and cursor location arrays) were written in C program in the code to store the phone numbers in the memory.

GSM communication testing

The lab staff can query the laboratory environmental parameters by texting the command “ENV” to the intelligent monitoring system. As can be seen in Figure 10, the current temperature, relative humidity, and lighting level status were sent to the designated cellular phone via GSM communication.

When unauthorized students entered the safeguard cage, the alert text messages (from one testing day) shown in Figure 11 were sent to the designated cellular phone via GSM communication. These text notifications can alert a lab manager/staff immediately to prevent potential accidents within the footprint of the robot safety cage.

We also studied the accuracy of the GSM technology/module used in this project as affected by mobile network signal strength and network rush hours. The robotics laboratory is located in an urban area with great 2G mobile network signal. It is noted that 2G network uses circuit-switched data modems that limit data users, i.e., data transmission may encounter interference if multiple users are simultaneously using the same bandwidth of the networks (e.g., 1900 MHz). According to T-Mobile, nearly no other local customers use the 1900 MHz frequency band. During the testing phase, the intelligent monitoring system (with the GSM module) was verified at different times of the workdays. The testing results showed that the performance of the GSM system (i.e., GSM accuracy) was not influenced by network rush hours (e.g., noon and late afternoon when the majority of mobile phone users used the cellular network on campus).

It should be pointed out that GSM networks store user information on removable SIM cards. Any person with the qualifications to access to the GSM module can easily swap networks by putting in another SIM card. As such, GSM security needs to be considered to protect data transmission in the future.

Environmental sensors and OLED display testing

Figure 12 illustrates the system “Disarmed” status and laboratory environmental parameters (temperature: 75.2°F; relative humidity: 42.00%) on the OLED display when the key switch was in the “Disarmed” position. A red-color LED was illuminated in the front panel of the enclosure.

Safeguard cage presence sensing and robot power control testing

To cover the whole aperture to detect all unauthorized entry toward the robot safety cage, four retroreflective photoelectric sensors (Figure 13) were installed in a vertical orientation at the safeguard cage entrance to form safety light curtains. The average spacing between light beams was about 18 inches, which was sufficient for body detection. The first light beam from light curtains was placed at 10 inches above the ground to prevent anyone from crawling under it. When any of the light beams were blocked, the sensors converted body detection into electrical signals that were sent to the ATmega1284 microcontroller. As soon as the microcontroller received the electrical signals from light curtains, it controlled the instantaneous contacts of the power relay to disarm the power supply of the robot system. No measurable time delay was found between the light curtain activation and robot power shutoff.

Conclusion

This paper presents the overall design, development, and hardware implementation of a GSM-based intelligent robotics laboratory safety monitoring system in order to prevent unauthorized students from coming into the working area of the robot and to protect them from injuries caused by the unexpected movement of the robot. The testing result indicated that this intelligent monitoring system was able to instantaneously shut off the power supply of the robot when unauthorized students were detected. At the same time, alert notifications can be wirelessly sent to the lab manager’s cell phone via GSM cellular networks to prevent potential accidents in the workplace. This intelligent monitoring system—combined with the protective safeguard cage—can create a safe robotics lab operating environment for students and faculty.

Acknowledgements

The authors wish to acknowledge the Faculty Project grant and the financial support from the Center for Integrative Natural Science and Mathematics (CINSAM) at Northern Kentucky University. In addition, the authors would like to thank the journal reviewers for their comments and suggestions for improving the quality of this manuscript.

References

Autodesk-Eagle. 2020. PCB layout design. https://www.autodesk.com/products/eagle/overview

Gagliarducci, M., Lampasi, D.A., & Podestà, L. (2007). GSM-based monitoring and control of photovoltaic power generation. Measurement, 40(3), 314–321.

Microchip. 2020. Atmel Atmega1284 microcontroller. https://ww1.microchip.com/downloads/en/devicedoc/atmel-42718-atmega1284_datasheet.pdf

OSHA. 2020. OSHA Technical Manual (OTM) | Section IV: Chapter 4. https://www.osha.gov/dts/osta/otm/otm_iv/otm_iv_4.html#app_iv:4_1

Ramya, V., Palaniappan, B., & Sumathi, V. (2012). GSM based embedded system for remote laboratory safety monitoring and alerting. International Journal of Distributed and Parallel Systems, 3(6), 31–49. https://doi.org/10.5121/ijdps.2012.3604

Seeed Fusion. 2020. PCB manufacturing & prototype. https://www.seeedstudio.com/fusion_pcb.html

Sergeyev, A., & Alaraje, N. 2010. Promoting robotics education: curriculum and state-of-the-art robotics laboratory development. The Technology Interface Journal, 10 (3).

Zheng, X., Li, L. & Shao, S. (2016). A GSM-based remote temperature and humidity monitoring system for granary. MATEC Web of Conferences 44. https://doi.org/10.1051/matecconf/20164401060